Location of pumps in a chemical installation layout mainly depends upon these below consideration.

1. Hazardous area classification recommended safe distance.

2. To satisfy NPSH requirements.

3. Distance to permit access for Normal operation and maintenance.

4. According to piping study.

General location of pump in a chemical plant:

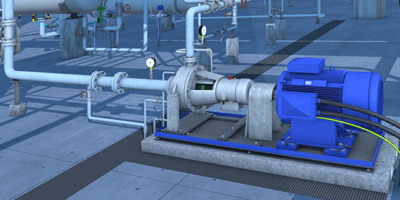

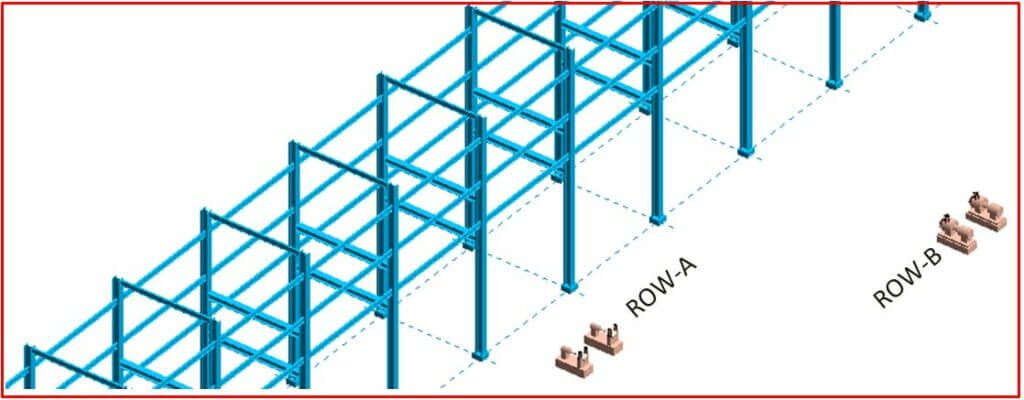

1. Pumps shall generally be located in a row or in more than one row under / adjacent to the pipe racks. Pump handling non-flammable product can be placed directly under the pipe rack where as the pumps handling flammable product to be avoided directly under pipe racks carrying major product lines, air coolers or vessels.

Placing pump under/adjacent is suitable because we can take support for pump piping from pipe rack steel/concrete structure and no additional structure design is required saving cost and time.

Hydrocarbon leaks to the electric motor are considered minimum under the pipe rack, where as in other areas the equipments dealing with hydrocarbon in vicinity can be a grave concern. Some pipe racks usually have hydrocarbon bearing air coolers located at top, in that condition the suitability of installing pump needs to be seen. For this case the general rule from relevant codes can be followed, one such from IPS-E-PR-190 (Iranian Petroleum Standard) is provided below.

Pumps intended to handle flammable materials (which fall under the control of hazardous area classification) shall be located as per following

| Use of pumps | Under pipe rack | Under air cooled exchanger |

| Cold oil pumps | Acceptable | Acceptable |

| Hot oil pumps * | Unacceptable** | Unacceptable** |

| Light end pumps*** | Acceptable | Unacceptable**** |

* Hot oil means the oil whose operating temperature is higher than Auto-ignition temperature.

** A space of minimum 3 meter shall be provided from pipe rack, Hot oil pumps can be located under piperack, when the proper devices for fire protection such as fire detector, water spray etc. are provided.

***Light ends means the fractional distillates with boiling pressure range 110°c – 120°c, consisting mixtures of benzenes, Toluenes, xylenes, pyridine, phenol, cresol etc.

****Light end pumps shall not be located under the air cooled exchangers except where concrete decks are provided under air cooled exchangers. Light end pumps can be located under air coolers without concrete decks when proper measure for fire protection is made available.

If there is a possibility of hydrocarbon spills under pipe rack it can be placed at some distance adjacent to pipe rack in rows as shown in below Fig-1A.

2. Pumps can be placed under or near the equipment it serves. Generally drums and heat exchangers are less associated with oil spills so pumps can be placed directly under their support structure. In this case the support for piping is taken from the equipment support structure itself.

Pumps like vertical can type pumps are used when the Horizontal pump cannot satisfy the NPSH requirement. So it is impractical to place them far from the equipment however general operation and maintenance space and hazard area classified safe distance to be taken care of. On similar line pumps which operate close to vapour pressure (e.g boiler feed pump) and pumps operating on vacuum services are Placed close to the equipment from which it takes suction.

Pumps which require alloy or heavy metal suction lines also placed nearer to the equipment considering cost factor.

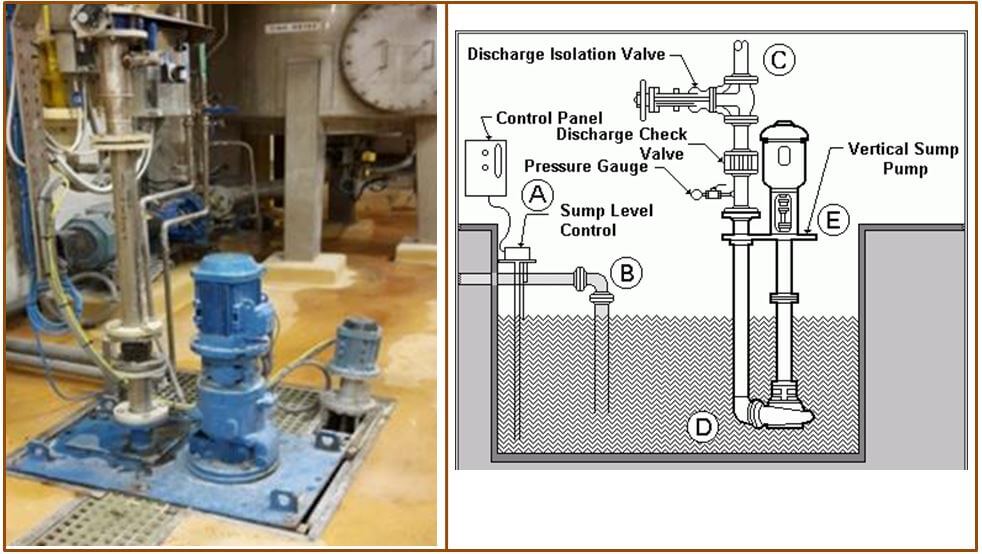

Sump pumps are used to remove waste material collected in a concrete or steel pit. This sump pumps are placed above the pit on ground level as shown in below image.

3 Pumps should be grouped together where possible for ease of operation and maintenance.

Recommended distances and good practises to follow :

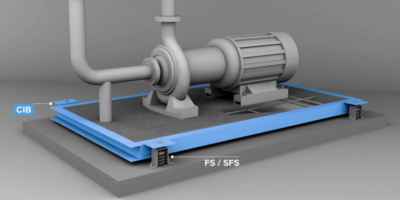

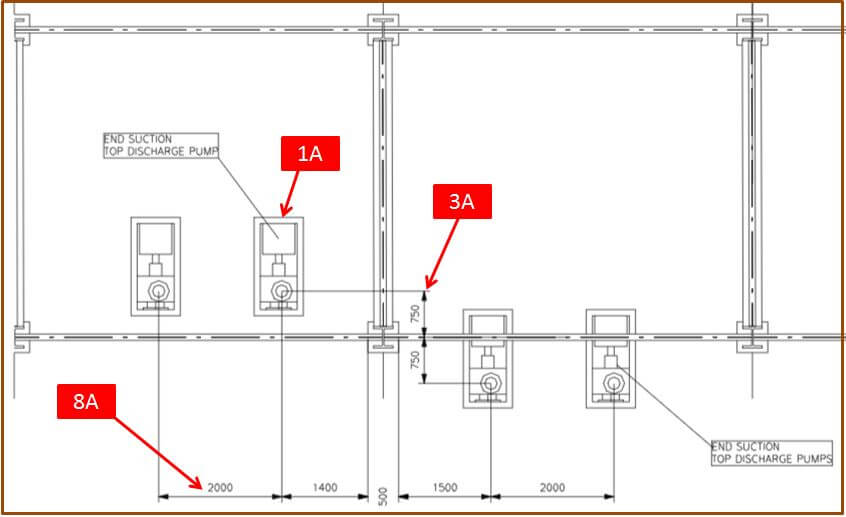

1A. The driver should be located towards the centre of pipe rack/access gangway. Clearance and piping should provide free access to one side of driver and pump.

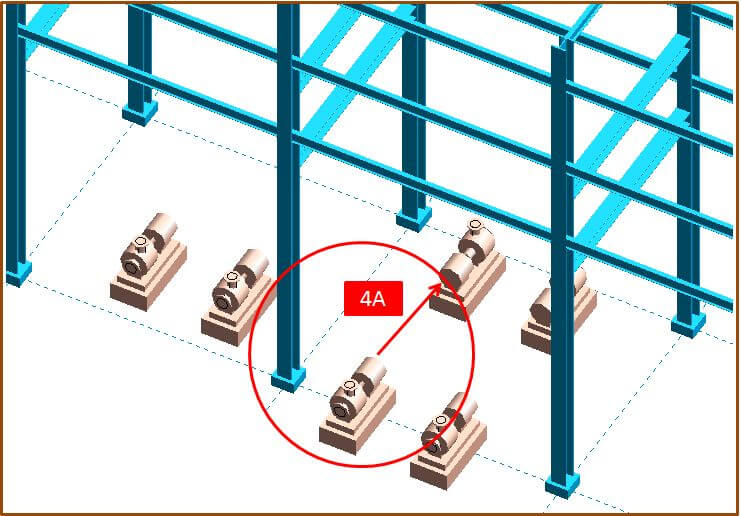

2A Pumps with respect to pipe rack can be placed with the wet end located outside the pipe rack and the driver should not extend more than 760 mm inside the centre line of pipe rack column.

3A Clearance between any structure /steel work and the pump discharge line shall be 750 mm minimum. A space of 2-2.5meter should be provided for working aisle.

4A. For pumps which extend inside pipe rack a minimum 3meter (10Feet) clearance is required between pumps at opposite side of the pipe rack. This clearance need not be in a straight line down a series of pump under the rack.

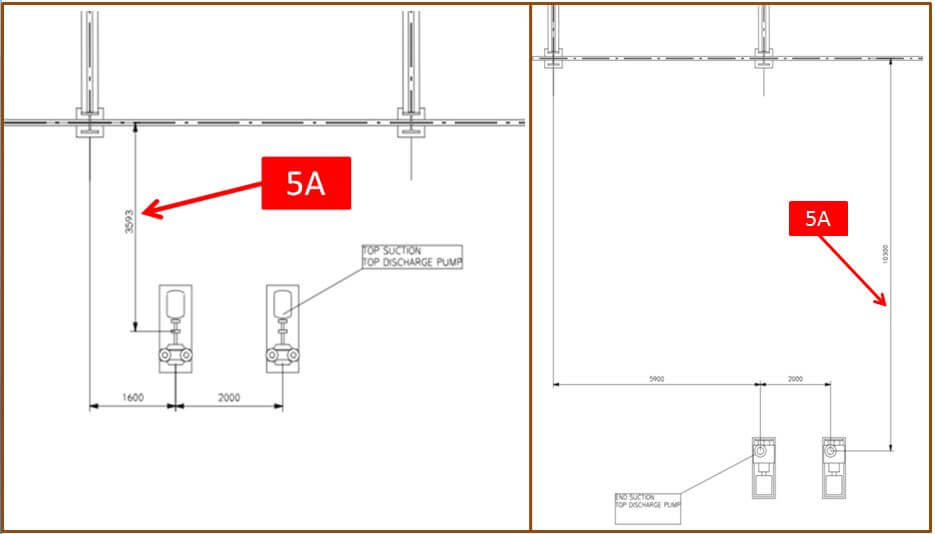

5A According to industrial risk insurer IM.2.5.2 (IRI) Pumps located between pipe racks and equipment rows should be located 3meter clear to avoid being hazardous to both equipment and rack.

6A Access should be provided to pump auxiliaries (e.g. seal pots, start button station, motor conduit connections etc). Clearance and access shall be provided for removal of pump drivers, pump rods, impeller and other parts.

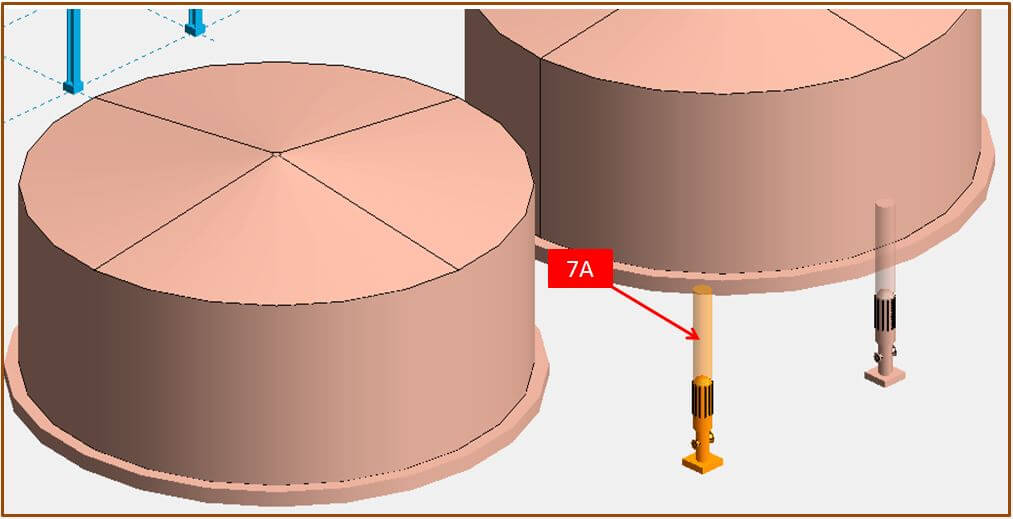

7A In vertical pumps the driver need to be removed vertically, so overhead maintenance distance for vertical pumps to be considered while locating these pumps.

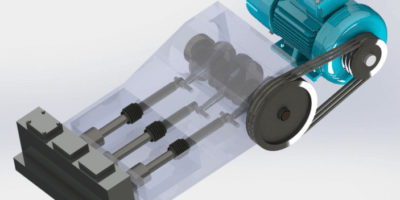

8A For Distance between 2 pumps can be below 2 rules can be followed:

8A.1 The suggested spacing for pump requiring a 0.5 meters to 1 meter wide foundation is 2 meter centre to centre. Anywhere from 1.5meter to 3.0 meter pump centre to centre distance is acceptable.

8A.2 Pump foundation to foundation centreline distance for

Small pumps -3.7kw and less mounted on common foundation – CL to CL distance as required according to designer’s discretion.

Medium pumps- 22.5 kw and less – CL to CL distance should be minimum 1 meter

Large pumps- above 22.5 kw – CL to CL distance should be minimum 1.5 meter

9A Client standard / local codes and regulation can be followed for Minimum distance of pumps from equipment e.g vessel, heat exchanger, tanks and buildings. Some of these are produced below.

process-unit-equipment-spacing Offsite-equipment-spacing