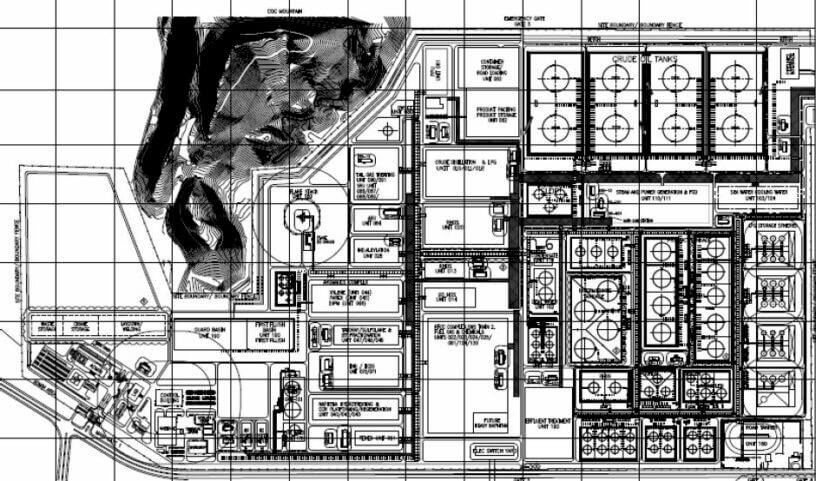

Before development of plot plan we should have the block dimensions of all plant and non plant buildings, rack width and length with shape, plant north direction, and wind direction.

Block layout should be followed as far as possible. The entire area should be subdivided into blocks. Layout of these block and facilities should be in sequential order of process flow.

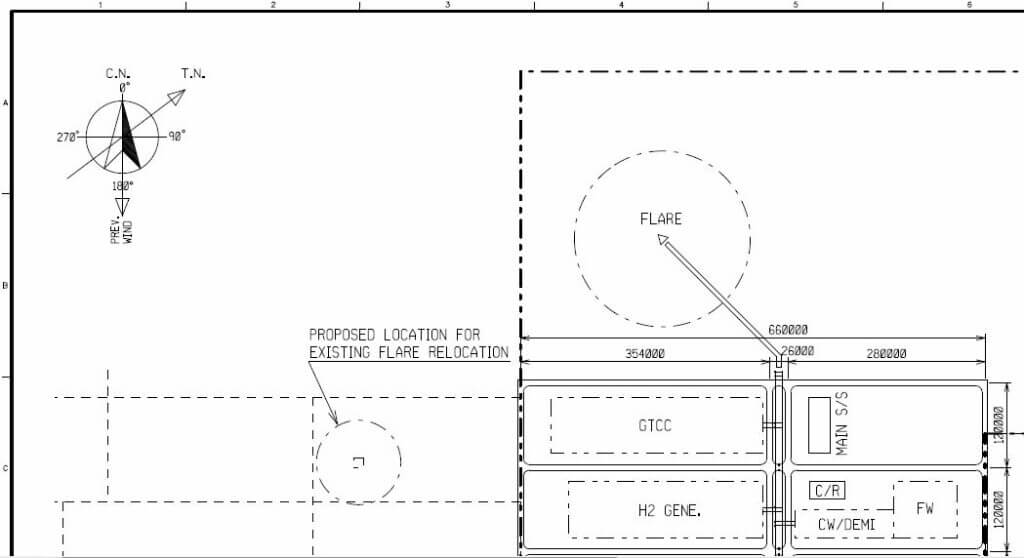

1. Flare location:

** Flare location should be 90 mitres away from process and non process buildings.

** It should be in upwind direction such that the flammable gases from hydrocarbon and other processing areas cannot be blown into the open flames by prevailing wind. This above is per OISD-118 directive mainly in onshore plants.

** As per API-14E directive for off shore installations it is downwind. The exact wording from the said code is produced here i.e “vent or flare structures should be designed to prevent buckling caused by wind movement. vent or flare structures should preferably be installed on the downwind side of platform, taking into account helicopter and boat approaches etc.”

** Areas around flare should be paved and vegetation should be clear to ensure they will not be ignited.

** Fencing around flare to be considered to protect people, livestock and wildlife.

This below image shows an example location of flare note the wind direction as well as the area near flare.

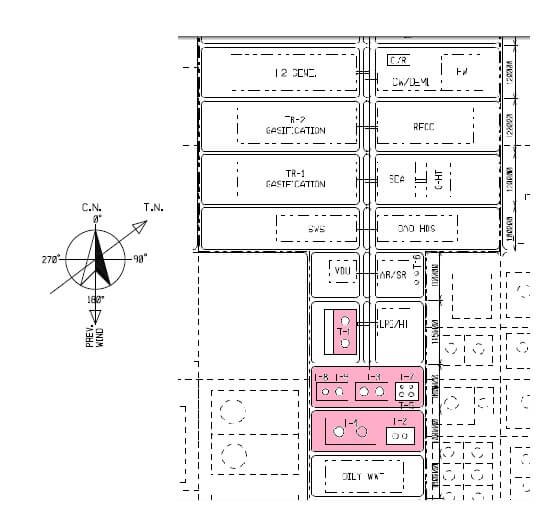

2. Roads:

** Road width 8 mitres or 6 mitre and plant inner road should be at least 4 mitres. Roads should have 1 mitre shoulder at each side and then storm water drain.

** Process units should be surrounded by approachable roads.

** There should be alternative access road for each block/facility in plant so that it can be approached for fire fighting in the event of blockage in one route.

** Two road approaches from the highway/ major road should be provided, one for

Employees and other for product/material movement.

** Ware house near material entry gate to avoid traffic inside process area. Provide Weigh Bridge near material handling gate.

3. Tank farms:

** Storage tanks shall be planned in a separate block with roads all around for access and safety.

** Tank farms should be in downwind direction.

** Storage tanks should be located at lower elevation.

** Storage tanks should be grouped according to product classification.

2. Effluent treatment plant (ETP):

** Waste from different plant need to be collected at effluent treatment plant .If this drainage done through gravity flow pumping capital can be saved. Due to this requirement the location of ETP should be at low height area.

** it should be downwind side from process and non process buildings so that foul odour should not come to office or to men working at process buildings.

** ETP should be located minimum one block away from process unit area, close to disposal point and by the side of plant overall boundary.

2. Cooling tower:

** Cooling tower should be located downwind side of compressor house or any air intake facility so that moist air from cooling tower should not be taken by them.

** Cooling tower should be located downwind side Process equipments and substation so that fog developed will not cause corrosion or obstruct vision or short circuiting.

2. Substation:

** Location of substation at approximately centre of the plot so that cabling is minimum.

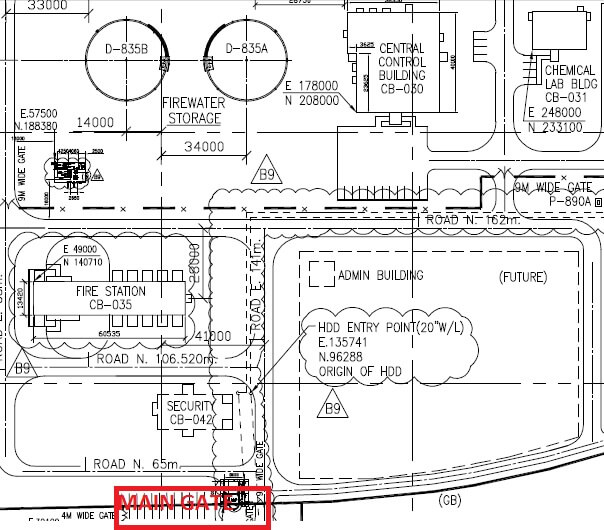

2. Fire station:

** Fire station ,fire water storage and fire water pump house shall be located at a safe distance away from hazardous area .

** should be upwind of process units and hydrocarbon area.

** Straight approach to critical areas required.

** should be located near main gate.

2. Control station:

** Control room shall be located upwind of process plants in a non hazardous area. .

** It should not be located in lower level than surrounding plants and tank farms.

** No structure shall be there that would fall on the control room in care of blast.

2. Sulphur recovery unit/Petro coke storage Unit :

** Sulphur recovery unit deals with hydrogen sulphide also called sour gas and sulphur dioxide which are hazardous element. These have potential health effects if inhaled or through skin contact. Liquid sulphur also has fire hazards.

Petroleum coke and storage facilities have possibility of a combustible dust explosion.

** considering these above Sulphur recovery unit, sulphur loading area, petroleum coke storage and handling facilities should be located close to product movement gate and away from process units, populated area

** Equipment drawing air e.g air compressor, air blower and Fans should be located away from sulphur recovery unit and handling facilities.

2. General points :

** Green belt area should be 1/3 of total plot area.

** consider future expansion (50%) and floor space index to be 50% of construction area.

** Safe distance between all units and equipments as per governing statutory regulation.

** Process units away from traffic in higher ground.

** Ware house near material entry gate to avoid traffic inside process area. Provide Weigh Bridge near material handling gate.

** Rail loading facilities should be located along the boundary of plant.

NOTE: The above article is derived from Oil Industries Safety Directorate – OISD Code. In Any case GE GAP 2.5.2 , Petroleum rules/Act , client standards and country specific codes and standard should also to be followed.

seyed aliakbar MIRGHADERI

hi, very suitable site. thanks a lot.