What is an Oil mist eliminator

It is a filtration system designed to control or eliminate oil mist and particulates from the air stream of vents in lubricating oil systems used in turbo machinery and engines, such as gas turbines, steam turbines, turbo compressors, turbo generators, reciprocating engines, high-speed couplings, and gearboxes. It helps in venting mist free air to the atmosphere and also reduces the visible plumes from the oil vents.

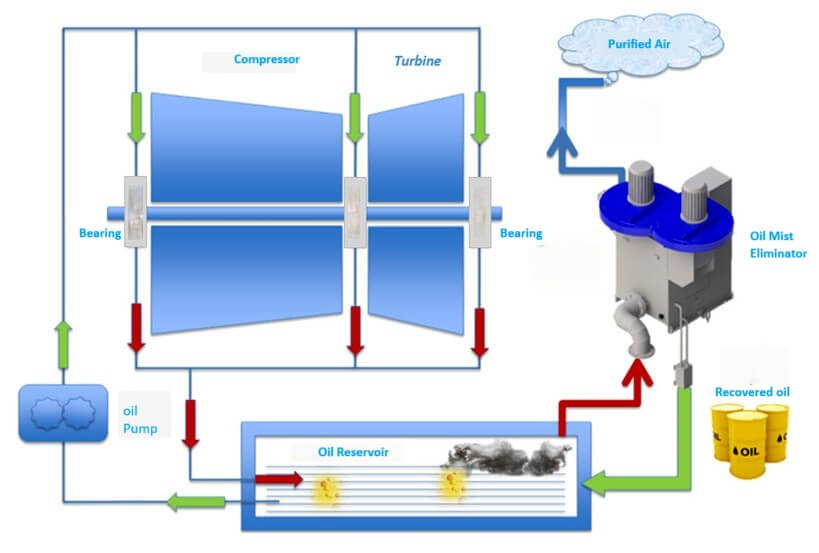

Below is an image showing the flow of oil and oil mist through a turbine system that utilizes an oil mist eliminator.

Why do we need an oil mist eliminator

Environmental aspect

When lubricating oil systems in turbomachinery are exposed to the heat and mechanical forces of the bearings, they produce a significant amount of mist and vapor. If these mists and vapors are released directly into the atmosphere through vents, they pose environmental hazards. Environmental regulation for oil mist is becoming stringent in terms of air quality (<3mg/m3 required). Oil mist eliminators contribute towards the reduction of the carbon footprint of the plant.

Economics aspect

Any untreated oil mist that passes through a vent is essentially wasted. However, by installing an oil mist eliminator in the same system, we can recover the oil and reduce expenses. For instance, a reservoir venting at 340 Nm³/h with a 100-ppm oil mist concentration can lose almost 380 liters of oil annually unless an oil mist eliminator is used.

Safety & maintenance aspect

The oil mist and condensing vapors can settle on adjacent areas like ladders and walkways, creating safety risks for the plant and its personnel. Breathing in these vapors also presents a health hazard for workers. These untreated mists can make the nearby machine and equipment surfaces very dirty and this way it affects the maintenance of the plant.

Types of oil mist eliminator

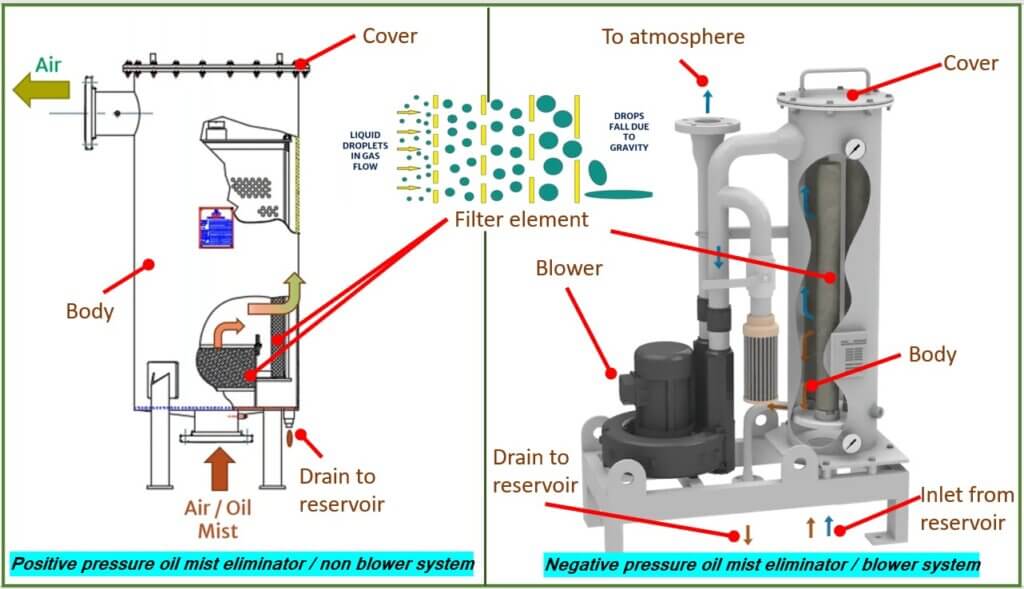

There are mainly two types of oil mist eliminators used widely and are listed below

- Positive pressure oil mist eliminator/non-blower system

- Negative pressure oil mist eliminator/blower system

Positive pressure oil mist eliminator / non-blower system

This is used in a lube oil system that maintains pressurized oil at the bearings, thus keeping slightly positive pressure in the lube oil reservoir as compared to the atmosphere. Positive-pressure Oil Mist Separators also help to avoid overpressure in the tank, which could form while accumulation of oil mist. Due to the reservoir’s pressure being slightly higher than the atmospheric pressure, here oil mist flows from the reservoir into the oil mist eliminator.

This type is mainly used in aero-derivative engine/turbine system.

Negative pressure oil mist eliminator/blower system

These types are used in gas turbines or compressor lube oil systems which are designed to operate at negative tank / negative bearing pressure. Due to this, the oil mists from the reservoir won’t flow into the oil mist eliminator by itself. Here the oil mists have to be sucked with the help of a suction blower or fan. This also helps in maintaining the negative pressure at the tank for which the lube oil system is designed.

Negative pressure on the bearing prevents the lube oil from going past the bearing in the engine to the external environment. Negative pressure in the reservoir helps the lube oil drain from the bearing to return to the reservoir without effort.

How oil mist eliminator works

Inside the eliminator, there are filters or demisters, whose number, type, and arrangement may vary between manufacturers. However, they all serve the same fundamental purpose: separating oil droplets from the vapor. Through the coalescing process within the filter cartridges, the oil droplets gradually form larger droplets. These larger droplets then accumulate and drain to the bottom of the vessel, eventually flowing back to the reservoir via the drain connection. Below is a figure that shows the parts of the oil mist eliminator and the flow through it.

Coalescence is the process of two or more droplets or bubbles of a substance merging into one larger droplet, which filters out easily because they are heavier.

Below is an animation that demonstrated how it works.

Where an oil mist eliminator is located

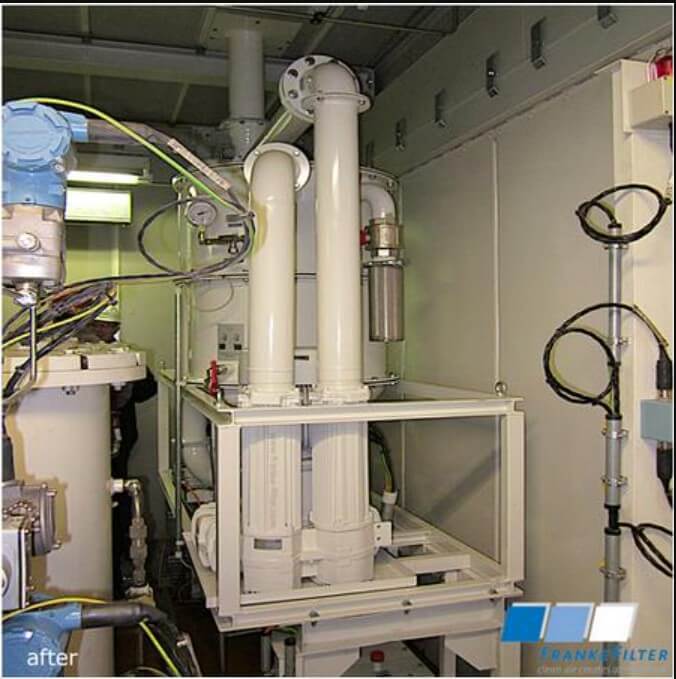

In most cases, the oil mist eliminator is mounted on an elevated structure near the lube oil reservoir, or if it’s small it is mounted directly on the vent pipe from the reservoir with some added supports. Anyhow, the vent line from the reservoir to the oil mist eliminator should be short considering the requirement for less back pressure. Below are some images showing the OME for different engines.

What information should be provided to the oil mist eliminator vendor to ensure proper sizing and selection?

Below are some common information the vendor needs

Flow Rate

The volume of gas that needs to be treated. If the oil mist eliminator is treating the reservoir vent flow, the flow rate can be the Normal venting capacity as per API STANDARD 2000.

For example, considering a Lube oil reservoir of 2500 gallons and a total oil flow rate of 200 GPM:-

(1) The venting requirement for thermal outbreathing is 40 SCFH per Table 2A Api Std 2000.

(2)The venting requirement for maximum oil movement into the reservoir is 6 SCFH per barrel per hour of liquid flow or 6 SCFH/42 GPH per Api Std 2000 table 1A

The flow rate for this reservoir is 200 GPM = 12000 GPH, so the venting requirement for max oil movement into the reservoir is calculated

![]()

Total normal venting capacity = sum of venting requirement for thermal effect (1)+ venting requirement for liquid movement (2)

Total normal venting capacity = 1714 + 40 = 1754 SCFH, and this can be our minimum vent flow rate.

Pressure drop

The acceptable pressure drop across the Mist eliminator affects the system’s overall efficiency. Normally the reservoir vent pressure drop should not exceed 0.0726 psi (500.6 pa).

Operating Temperature and Pressure

The temperature and pressure (in bar or psi) of the gas stream should be provided

Oil Type

The type of oil used in the system to be provided, as different oils may have varying viscosities and properties.

Desired Separation Efficiency

The required efficiency of the OME in removing oil mist is usually expressed as a percentage. Normally the efficiency should be 99.97% of all 0.03 micron and larger oil particle.

Environmental and Safety Regulations

Any relevant environmental and safety standards that the OME must comply with.

Leave a Reply