In terms of equipment arrangement process unit plot plans can be divided into two types of configuration as stated below

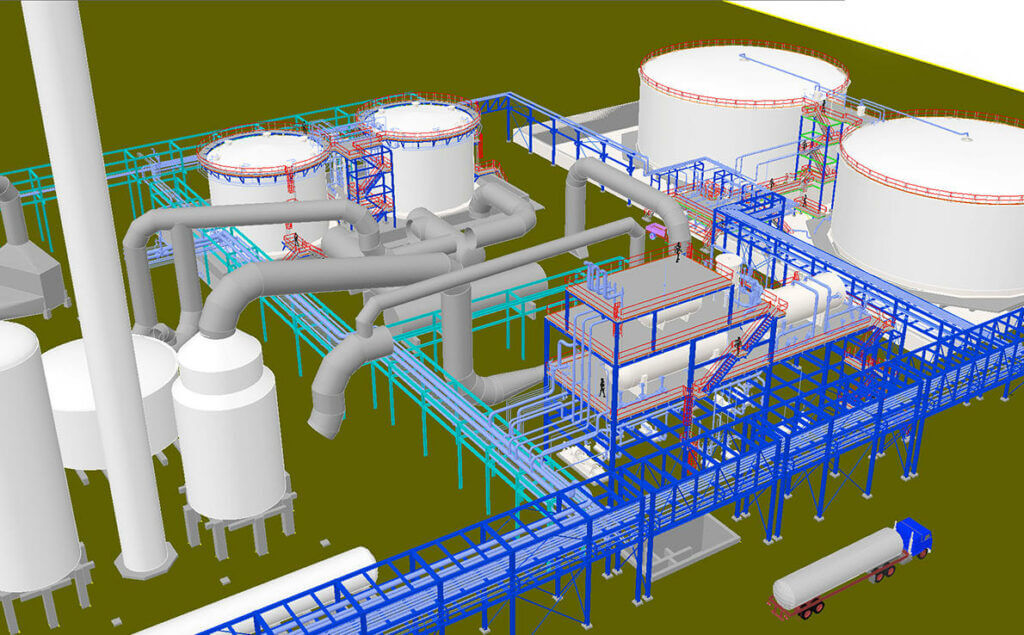

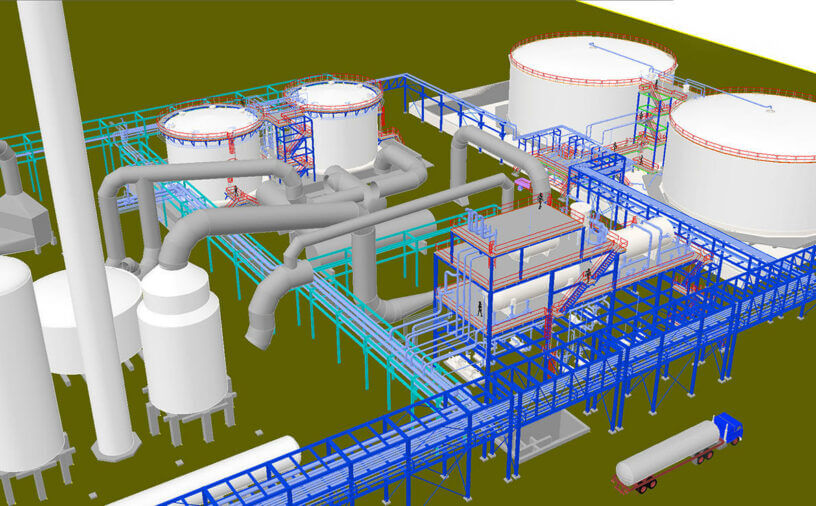

1. The grade mounted horizontal inline arrangement:

Here unit is located in a square or rectangular area. The main pipe rack is placed at approximately center of the area.

Equipments are placed either side of the central pipe rack with auxiliary roads in-between for access.

This kind of arrangement is mostly seen in refineries.

Advantages:

Equipment are located at grade so it’s easy to construct and more accessible to operation and maintenance.

Disadvantage:

Area required is large. Length of cabling, utility, feed and product piping required is more.

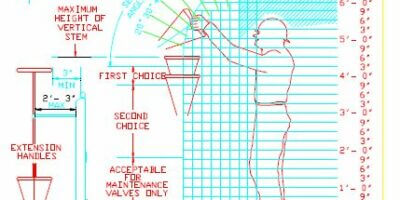

2. The Structure mounted vertical arrangement:

Here the unit is basically multilevel of steel or concrete structure .Equipments are placed as per process flow in each level.

There are openings in floors for piping and cabling interconnection also the pipes and cabling can be routed outside the structure with supporting from outside member.

For operator access either staircases or elevator is provided. Equipment maintenance is usually done with use of hitch points, trolley beams or travelling cranes. The equipment drop points at grade should always be marked in this type of plot plans.

Advantages:

Area required is less. This can be arranged as a enclosed/ in-house facility where the climate condition or process requirement demands.

Disadvantage:

Difficult to construct than grade mounted plan. Operation and maintenance access is not as par in comparison to a grade mounted plan.

Leave a Reply