Process plants deal with fluids those are mostly chemical in nature with varying pressure and temperature .these fluids are transported from one point to another through pipes. The operations must be leak free.

Plants are designed for certain no’s of years, most commonly for around 20 years. In these life cycle years it shall contain

1. The fluid with varying temperature and pressure,

2. Corrosion due to fluid and outside environment,

3. Stresses generated due to plant operation

And it must not fail.

To satisfy these material used to build a pipe must have high strength and ductility besides other properties like resistance to corrosion, commercial availability etc. There comes metal into picture and that is the reason why we see most of the pipes used in plants being metallic rather than plastic or rubber. As a matter of fact plastics and rubber are also used but not as common as metals.

So after the designer has chosen the material of pipe a question comes how much thick should be the pipe so that it will satisfy previously said conditions.

ASME has laid down the Procedure to calculate this. We will explore this with an example and detail calculation.

As per ASME B 31.3 – Para 304.1

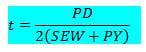

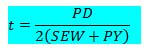

The required thickness of straight section of pipe shall be determined by following equation (1a)

![]()

Where tm = Minimum required thickness

t = pressure design thickness

c = mechanical allowance (thread and grove) +corrosion and erosion allowance

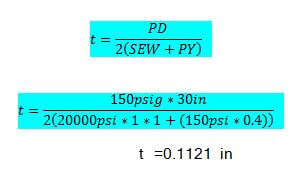

to calculate t = pressure design thickness in above it has given formulae in para 304.1.2

that says for t ≤ D/6 the internal pressure design thickness for straight pipes shall not be less than the calculated in accordance with either eq (3a) below or (3b)

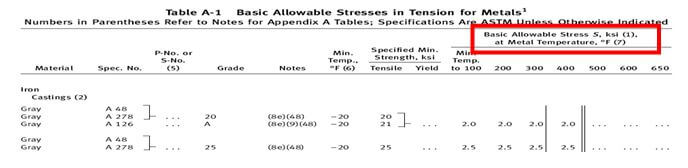

Where P = Internal design pressure (psig)

D = OD of pipe (in)

S =Stress value from material table A-1 B31.3 (psi)

E = Weld joint quality factor from Table A-1a (for casting) or A-1b (for tube/pipe)

W = Weld joint strength reduction factor from Para 302.3.5.e

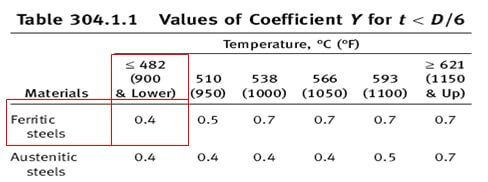

Y = Temp dependent co efficient from Table 304.1.1

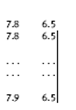

![]()

Equation (3b) (above) is seldom used and its used as a reference to verify/double check . So equation (3a) is considered primary.

EXAMPLE:

Now we will determine the required pipe thickness for a pipe

With fluid design temperature = 260°F

P = Design Pressure = 150psig

D = Pipe OD = 30in

Pipe material = A106 grade B (seamless)

C = Corrosion allowance = 0.125in

Mill tolerance = 12.5%

So to put in Equation 3a we know value of P,D only. Lets see how we can determine other values from code

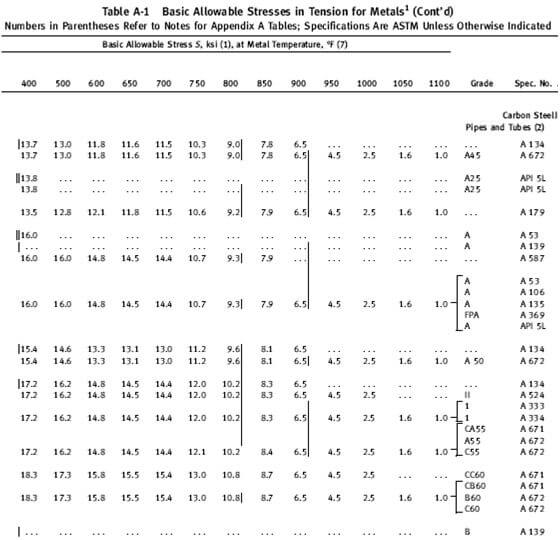

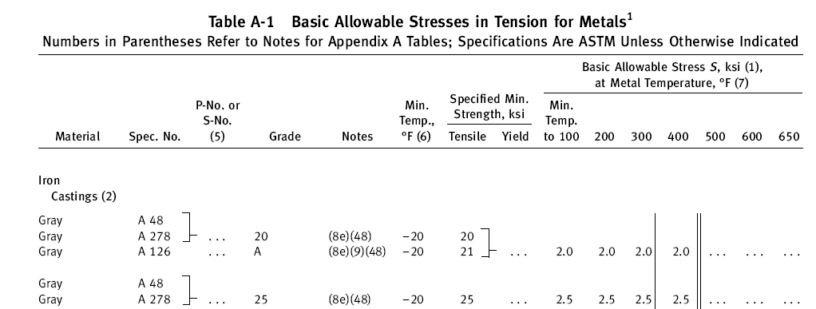

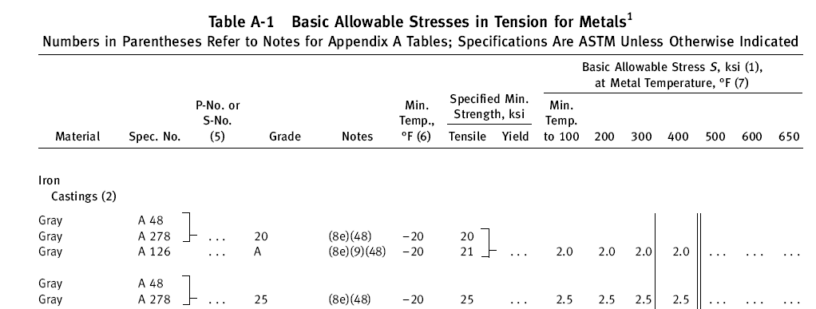

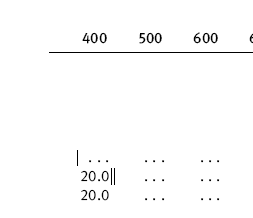

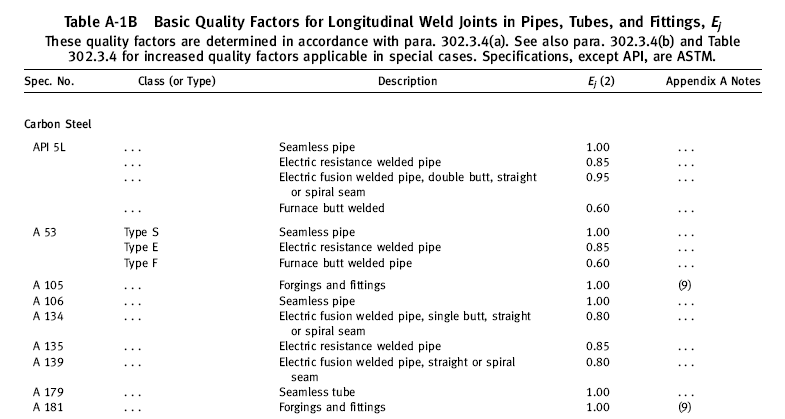

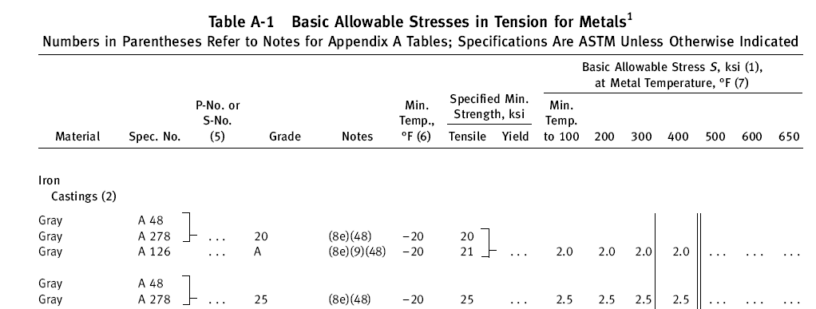

S =Stress value from material table A-1 B31.3 (psi)

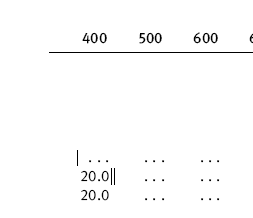

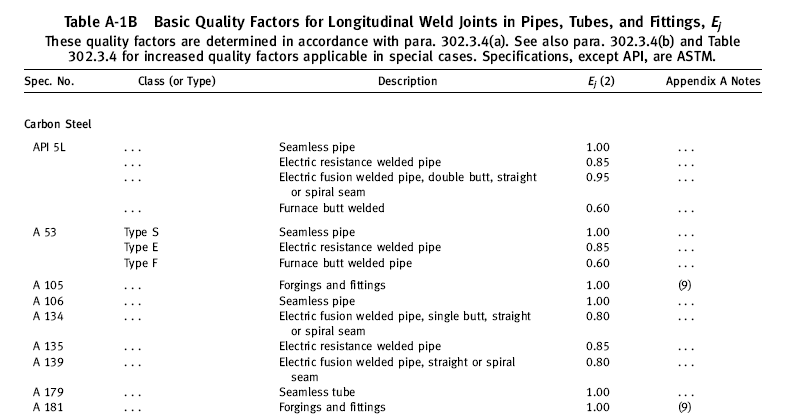

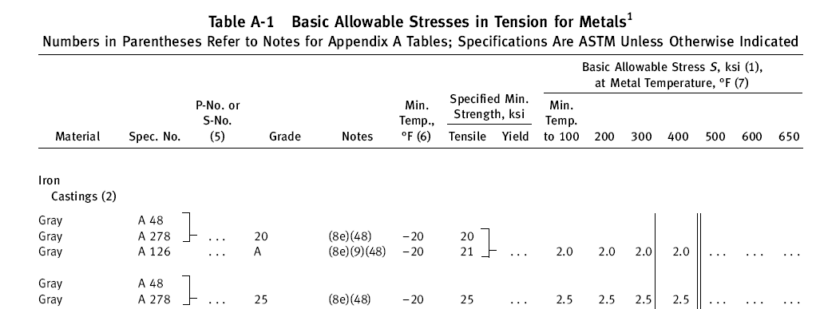

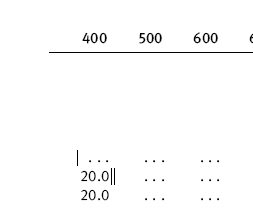

Go to table A-1 ,you will find this

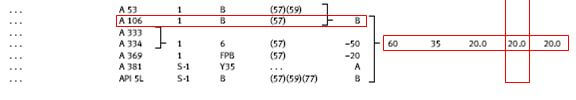

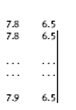

Now scroll and find carbon steel pipes and tubes where u can find A 106 gr B

This table gives the allowable stress value of materials at a temprature.

After finding the material grade row find the °F temperature column. And as shown above here you can find the allowable stress value S in (ksi) for A106 gr B for 200°F to be 20 ksi = 20000 psi.

For more temp scroll next page;

A single bar as shown below specifies the usage of material beyond this temperature needs special precaution.

A double bar as shown below prohibites the usage of material beyond this temperature

Screen shot of scrolled page as below for reference.

Allowable stress value for material in between the temperature specified in the chart can be interpolated.

That explains how to find S value for given material.

For our example we have got S = 20000 psi

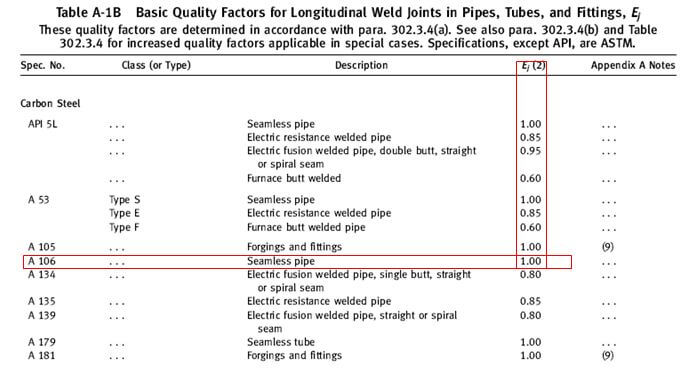

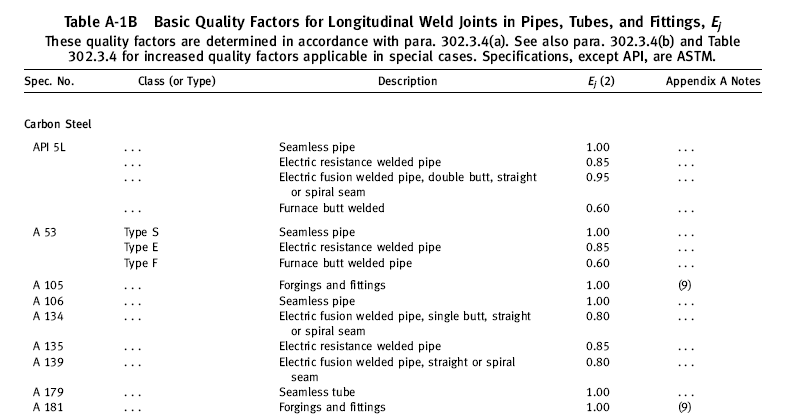

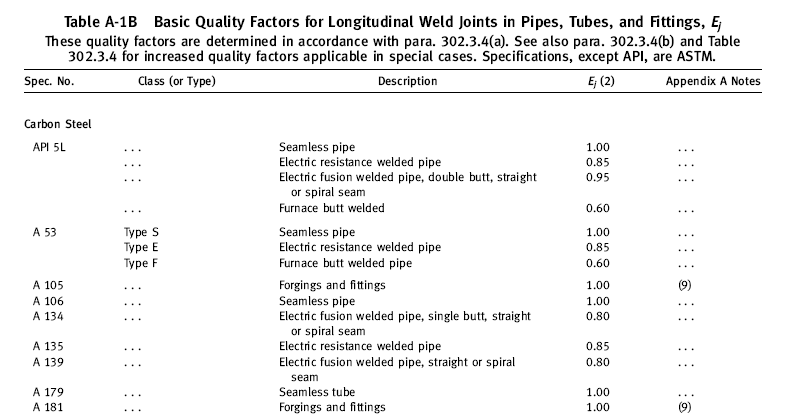

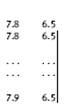

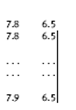

E = Weld joint quality factor

Go to table A-1b

Find the material grade and find Ej value as shown below for our case its 1.0 so

We got E=1

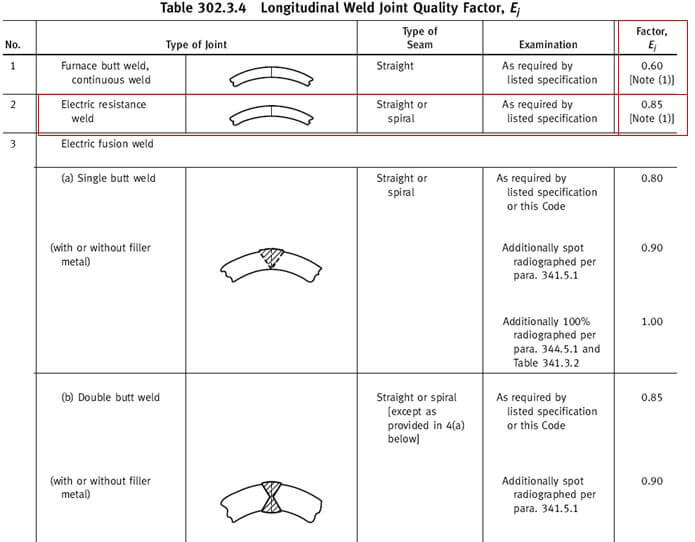

W = Weld joint strength reduction factor

Read para 302.3.5.e and then go to table 302.3.4

If the pipe is welded i.e not seamless then you have t multiply the value given in para 302.3.4 (Ej) with the above determined (E)

As our pipe is seam less the W value becomes 1.

If our pipe grade specified as Astm A 135 Electric resistance welded then W value would be 0.85 as shown below.

Y = Temp dependent co efficient

Go to table 304.1.1

As A106 gr B is ferritic steel go to ferritic steel row .And then find the temp column for your temperature.

below 200°F the value of Y as shown below is 0.4

Now that we have got all the values lets put it in the equation 3a

Putting the value of t in equation 1a tm = t + c

tm = 0.1121 in + 0.125 in = 0.237 in

this is the required minimum thickness after mill tolerance of 12.5% means the specified thickness by the designer may decrease 12.5% during the manufacturing process and even after reducing 12.5% pipe thickness should not be less than tm i.e 0.237in

So 100%-12.5% =0.875% = 0.237 in

t required = 0.237 in /0.875 =0.270 in = 6.858mm

as we will not get commercially available 30 in pipe with 6.8 mm thickness we have to go to b36.1 or any pipe thickness chart on net and choose the schedule thickness which is nearest to the calculated value

in this case its 30 in schedule standard whose thickness is 9.53 mm

************end************

Leave a Reply