Carbon Steel (CS):

Steel is basically a solution of carbon (C) in ferrous (FE). Carbon steel is the denomination for the steel that has almost no metallic alloy element added to it.

Carbon steel represents broad range of steel that contain

(a) 1% carbon (maxm)

(b) 1.65% manganese (maxm)

(C) 0.6% silicon (maxm)

Temperature range- it is used for temperature up to 425°c (800°f).

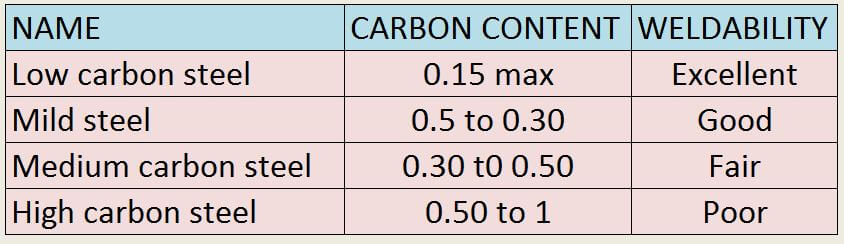

Types of carbon steel- generally there are 4 types of carbon steel

For each types of carbon steel piping element common ASME material standard and dimensional standard are provided below.

1. CS Pipes:

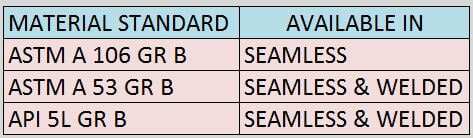

Commonly used CS pipes material standard:

Seamless pipes:

Welded pipes:

Welded pipes are commonly manufactured in two types.

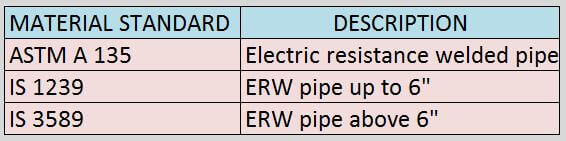

1. Electric resistance welded pipe (ERW):

Here no material is added during welding. Heat for weld is generated by giving –ve and +ve charge to the ends or by creating a strong electric resistance. So it’s called electric resistance welded pipe.

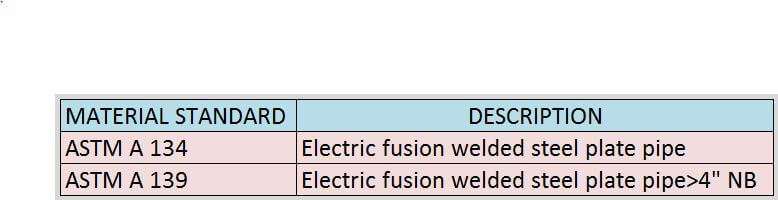

2. Electric Fusion welded pipe (EFW):

Here filler material is added during welding. Advanced weld process are used to accomplish the job.

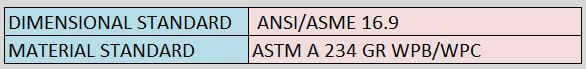

2. Wrought fittings:

Factory made Butt welded Elbow, tees, cap, Reducer etc. comes into this category.

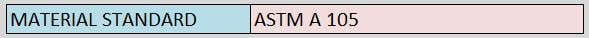

3. Forged Fittings:

Forges fittings like Flanges, sockolet, weldolet, Half Coupling, Forged valves comes into this category. For all of these forged fittings the material standard is one where as the dimensional standards varies

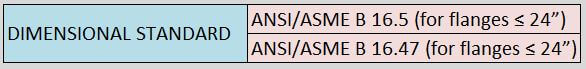

(a). Flanges:

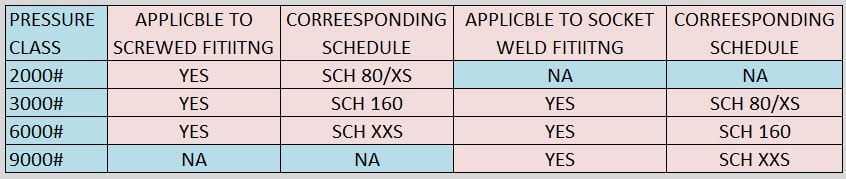

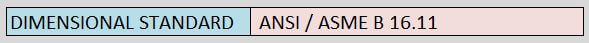

(b). Socket weld and screwed weld fittings:

Four pressure class are available for these type of fittings

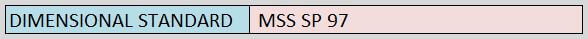

(b). Weldolet/sockolet:

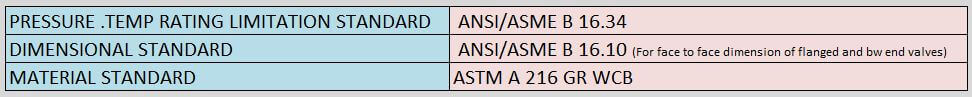

3. Cast Fittings:

Casted fittings like valves come into this category.

Leave a Reply