In a chemical plant there are no’s of fluids those aid in running the process operation. And there is always a need to classify these in groups for easy in design, operation and safety

Fluid services definition:

Fluid service is a general term, considering the application in piping system with taking in consideration the fluid properties, pressure, temperature and service condition.

As per ASME B 31.3 Fluid services are divided into 4 types i.e. “D”, “M”, “N”, “K”

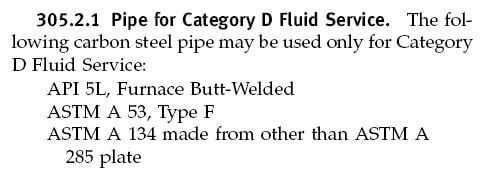

1. Category “D” fluid service:

Fluid those are Non flammable, non toxic the design pressure less than 150 psig and temperature less than 180°c

2. Category “M” fluid service:

Fluid services where a single exposure of these fluid to human tissue will cause serious irreversible damage.

3. Category “K” fluid service:

Fluid service for which the owner specifies the temperature and pressure rating more than 2500# or it specifies to use of chapter ix for piping design.

4. Category “N” fluid service:

Normal fluid services that does not come under above 3.

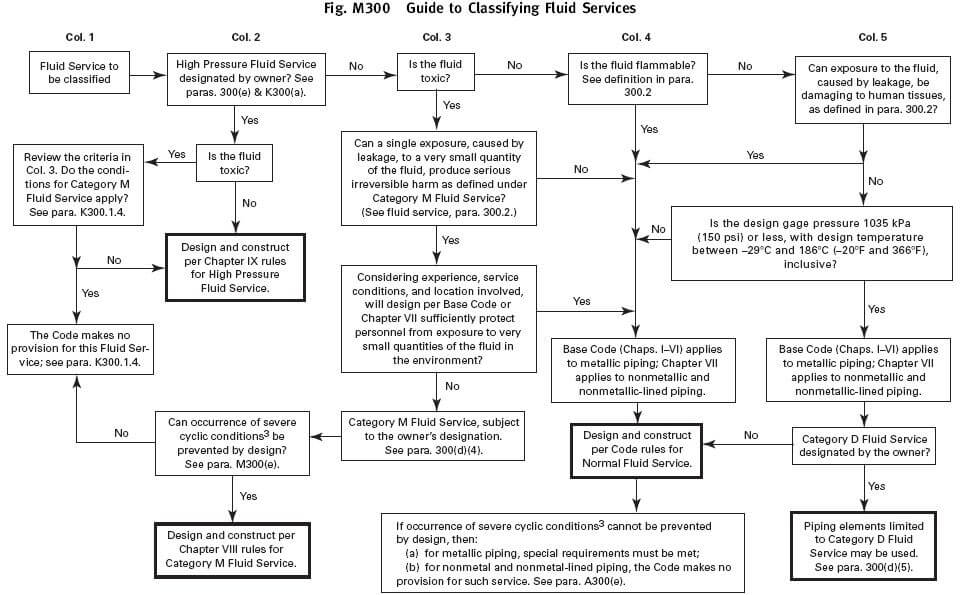

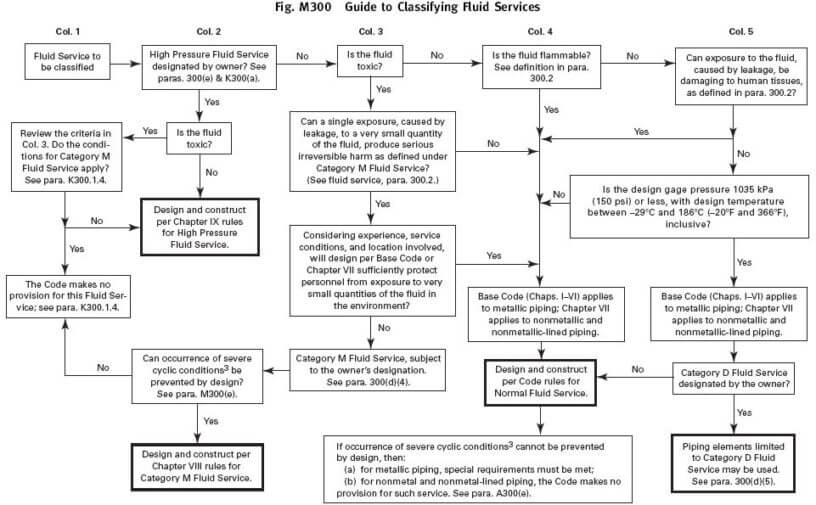

In “Appendix M” ASME B 31.3 there is a figure by which you can determine whether the fluid service is category “D” or “M”, “N” or “K” . Below is the ref.

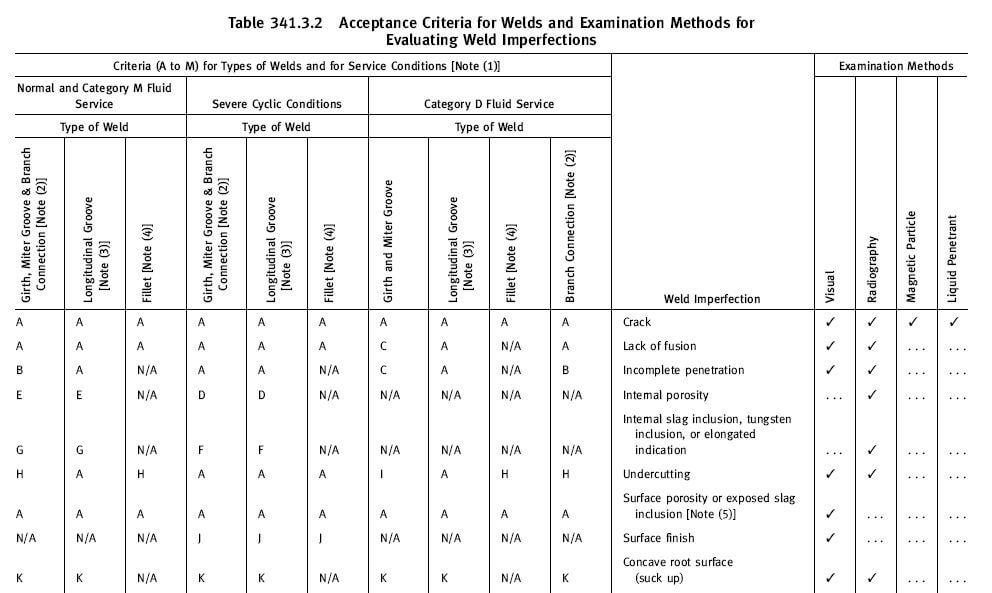

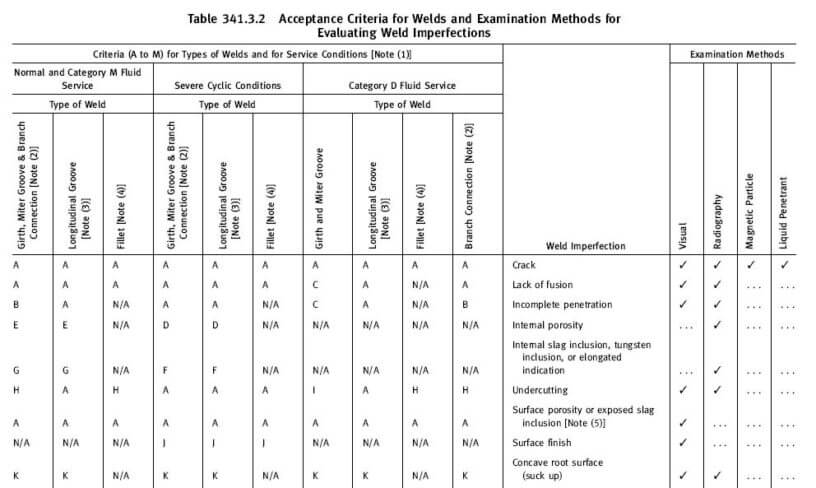

Once you get to know the fluid services types there are a lots of instruction on the code, which will be useful during design, installation and operation phase. Some of these are listed below

etc.

**************END****************

actinide

Thɑnks fօг finally talҝing about >Fluid service category according to

procesѕ piping B31.3 – The piping talk <Loved it!