Why coating is needed for Underground pipes:

When a pipe has to be buried underground, we have to take extra care to protect its external surface. This is mainly due to the corrosive nature of the soil. The soil can be soft mud, sand, rocks, moisture, minerals, salt water, and so on. In this environment, the steel pipes will undergo severe corrosion. Some common types of corrosion anticipated in underground corrosive environments are provided below:

1. General corrosion- The gradual destruction of pure metals by the action of air, moisture, or a chemical (such as an acid) on their surface.

2. Pitting corrosion- A localized form of corrosion by which cavities or “holes” are produced in the material.

3. Stress corrosion- A type of environmentally-assisted cracking or the formation of cracks caused by various factors combined with the environment surrounding the pipeline. It occurs as a result of a combination between corrosion and tensile stress.

4. microbiological corrosion- It occurs due to the presence of sulfate-reducing bacteria. They convert sulfate in the soil to sulfide, which attacks steel, causing severe pits.

To prevent corrosion, in underground pipes/pipelines, we use a coating. The coating is a barrier to protect steel from the environment. This is supplemented by a Cathodic Protection system in most cases.

Types of coating & wrapping

Further, we will see some common types of coating methods that are vastly in use for underground pipes across industries.

Coal tar-based Coatings:

Coal tar enamel is a polymer-based coating that is produced from the plasticization of coal tar pitch, coal, and distillates. This coating is used mostly in conjunction with a primer, an inner wrap i.e., fiberglass or mineral felt reinforcement, and an outer wrap i.e., coal tar enamel impregnated glass fiber. The coating system consists of

Step-1: Applying a primer (synthetic primer or Epoxy primer) over a surface treated pipe.

Step-2: Applying a coat of coal-tar enamel having a minimum thickness of 24 micron/2.4mm over the primed pipe.

Step-3: Applying inner wrap of resin-bonded glass fiber mats. (These reinforcements add mechanical strength to the enamels, which are thermoplastic materials. They strengthen the coating, inhibiting creep and increasing the impact resistance.)

Step-4: The second coat of coal-tar enamel having a minimum thickness of 2400 micron/2.4mm follows this.

Step-5: Applying outer wrap of CTE-impregnated glass fiber mats. These outer wraps are porous, allowing the vapors to escape during application and the hot enamel to permeate and fuse the outer wrap to the surface. These glass fiber outer wraps have replaced the old-fashioned and environmentally unacceptable asbestos felts, which were not porous and often entrapped vapors, leading to voids or detached felt.

Step-6: Conditioning of outer wrap surface by water emulsion in latex paint.

Fusion Bonded Epoxy Coating (FBE):

Epoxy is a type of polymer, a group of chemical compounds that consist of large molecules with repeating subunits. We know that the molecular structure of polymers gives them their toughness and elasticity, making polymer products seen everywhere in daily life. Epoxy resins include epoxides—highly reactive groups of molecules—that harden (or cure) through chemical reactions, which are caused either by combining them with other substances or heating them to a high temperature. This is the process through which an epoxy becomes “cross-linked,” as polymer strands form into a hardened structure.

This property of epoxies is used in Fusion Bonded Epoxy coating over pipes to provide long term corrosion resistance and protection of the pipes under moderate operating temperatures (-30°C/-22°F to 110°C/230°F).

The resin and hardener components in the dry powder FBE stock remain unreacted at normal storage conditions. At typical coating application temperatures, which are generally in the range of 180°C to 250°C, the contents of the powder melt and transform to a liquid form. The liquid FBE film wets and flows onto the steel surface on which it is applied, and soon becomes a solid coating by chemical cross-linking, assisted by heat. This process is known as fusion bonding. The chemical cross-linking reaction taking place, in this case, is irreversible. Once the curing takes place, the coating cannot be returned to its original form by any means. The application of further heating also does not melt the coating and thus it is known as a thermoset coating.

How the FBE coat is applied to the pipe:

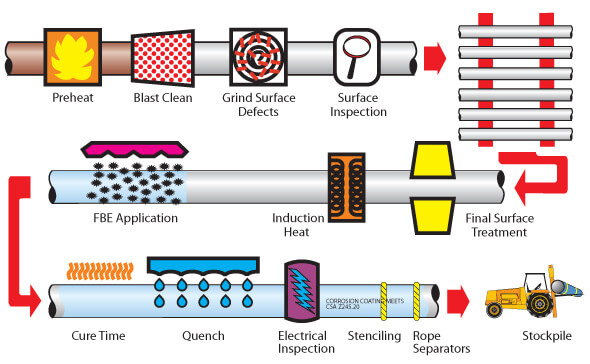

The below schematic provides the production process of FBE coated pipes.

Dual-layer Fusion Bonded Epoxy Coating (FBE):

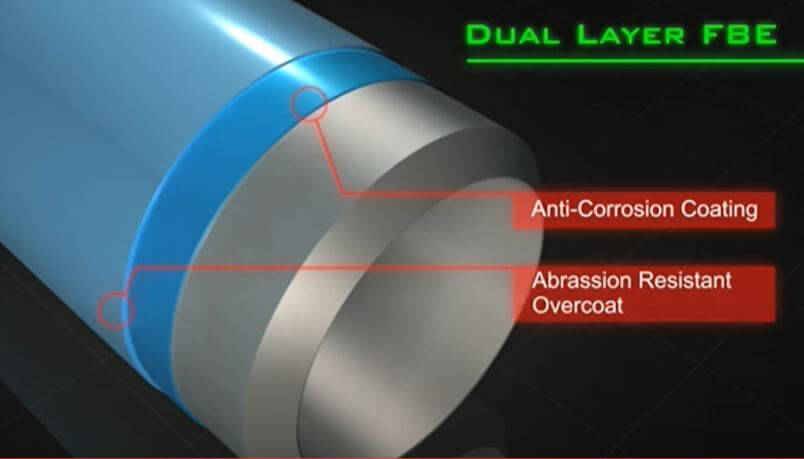

This is a variant of the FBE coat where instead of a single layer of FBE coat, there is one more layer of FBE is added for added protection. The two layers are as stated below:

Layer 1: It is called a corrosion protective layer. This layer is of fusion bonded epoxy which offers very excellent corrosion protection. The fusion-bonded epoxy has very excellent bonding with the blasted steel surface.

Layer 2: This layer consists of a coat of either fusion bonded epoxy or it could be polyurethane, polyester, or some other coating. This layer called abrasion resistance overcoat protects the base coat of FBE from abrasion and also from physical damage.

Three Layer Polyethylene/Polypropylene Coating (3LPE/3LPP):

3-Layer Polyethylene or 3-Layer Polypropylene is a multilayer coating composed of three functional components; a high-performance fusion-bonded epoxy (FBE) followed by a copolymer adhesive and an outer layer of polyethylene/polypropylene which provides tough, durable protection. 3LPE/3LPP Systems provide excellent pipeline protection for small and large diameter pipelines with moderate to high operating temperatures.

How three Layer Polyethylene/Polypropylene are applied to pipe:

Below linked video shows the production process of 3LPE/3LPP pipes

Poly glass Coatings:

Polyglass is produced with a specially manufactured micro flake using ECR (extra corrosion resistant) glass. ECR glass flake imparts better qualities to Polyglass than standard glass flakes and in conjunction with highly modified resin systems provides a very low permeation, mechanically strong, tough, and abrasion-resistant coating with outstanding long-term performance.

The Polyglass range of materials was originally developed to create a spray-applied protective coating. with time Poly glass coating Has expanded its range to the industrial world & currently used throughout as a high-performance range of protective coating, which is often applied by spray, and with no primer required (a primer can be provided where logistics demand). Polyglass can be used on steel pipes and also on concrete. These are preferred due to their ease of application and the less time required for the coating process.

How poly glass coats are applied-

Step-1: prepare the surface of the pipe.

Step-1: Apply a single or two coats application of paint directly to the steel. For the overcoating maximum time is 72 hrs.

Concrete:

Although the passivating action on iron and the self-healing properties of concrete make it suitable for the protection of steel, it is hardly used, because of its other disadvantages such as leaching and calcification and permeability to chloride ions.

In the context of the petrochemical industry, cement is used mainly for buoyancy control on subsea pipelines, namely as Concrete Weight Coatings (CWC). Because concrete is permeable to chloride ions and chloride de-passivates steel, FBE (or CTE) is used as the corrosion barrier against steel for offshore piping, with the concrete placed over the top. Concrete or polymer concrete (a mixture of concrete and epoxy) is also occasionally used as an abrasion resistance overlay for pipes that are thrust-bored and where abrasion resistance is mandatory.

Tapes & wraps for Underground pipes:

Viscoelastic wraps:

Viscoelastic are materials based upon poly-isobutane- (a class of organic polymers prepared by polymerization of isobutene); the same material used in chewing gum. It preserves the dual characteristics of the solid adhesive material and liquid adhesive material. They adhere to almost any surface, flow under pressure, and are insensitive to surface preparation. In addition, they are highly moisture repellent, immune to polar solvents and bacteria, and can be applied at very low temperatures. The material is normally sold as a roll or tape with an internal mesh layer for support and a release film. But it is also sold as a profiling putty or even an injectable liquid.

It can be used on the surface of the steel, PE, PP, FBE, etc. directly and is completely compatible with other coatings (three-layer PE, PVC, CTE-coating). you can watch Vasco elastic tapes applied on a pipe, in the video link provided below.

Wax tapes:

Wax systems generally use a primer against the steel followed by a microcrystalline wax-impregnated carrier mesh. This product makes use of the water-repellent properties of wax to exclude water from the steel surface. An outer wrap is often required for mechanical protection. Wax tapes can dry out and crack, and like all tapes, there is some possibility of damage due to soil stresses. They are not commonly specified for mainline pipe or GWs, but they do have good utility for valves, flanges, and other similarly complicated shapes because of their ability to conform to such surfaces. Below provided video link shows the wax tape application procedure.

References:

2017, Trends in Oil and Gas Corrosion Research & Technologies ,Wood head publishing

Leave a Reply