Alloy steel is the denomination of steel, where there is a low percentage of elements usually metallic e.g. chromium, nickel, magnesium, manganese, molybdenum added to strengthen the overall Material properties.

Temperature range- it is used for temperature above 425°c (800°f).

The need of Alloy steel over Carbon steel –

Steel is subjected to a process called creep at high temperature above 540°c creep is the phenomenon of reduction of strength over time due to high temperature. So at this temperature to protect the pipe from failing alloy steel is used instead of carbon steel.

Similarly at low temperatures usually below -20°c steel becomes fragile to sudden impact. So to avoid this alloy steel with batter material properties is used instead of ordinary carbon steel.

Alloy steel also increases corrosion resistance properties of steel at low and high temperature.

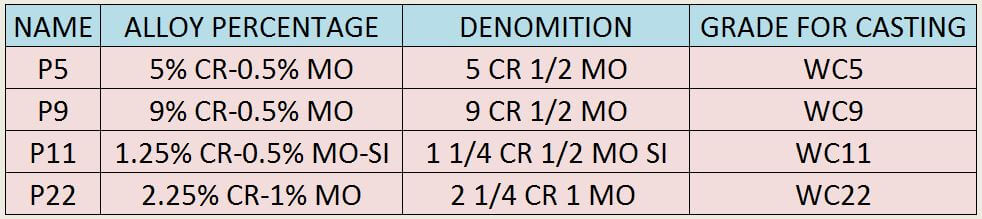

Commonly used alloy steel grades with alloy percentage is listed below-

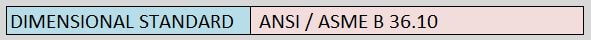

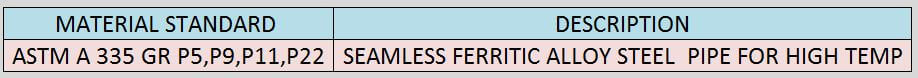

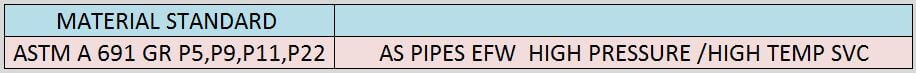

For each types of Alloy steel steel piping element, common ASME material standard and dimensional standard are provided below.

1. Alloy Steel Pipes:

Commonly used AS pipes material standard:

Seamless pipes:

Welded pipes:

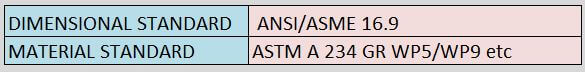

2. Wrought fittings:

Factory made Butt welded Elbow, tees, cap, Reducer etc. comes into this category.

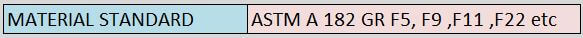

3. Forged Fittings:

Forges fittings like Flanges, sockolet, weldolet, Half Coupling, Forged valves comes into this category. For all of these forged fittings the material standard is same where as the dimensional standards varies

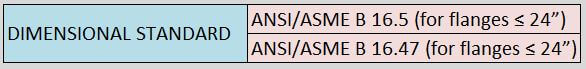

.(a). Flanges:

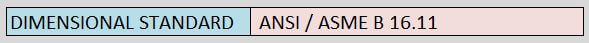

(b). Socket weld and screwed weld fittings:

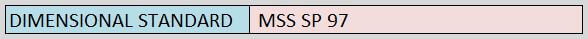

(b). Weldolet/sockolet:

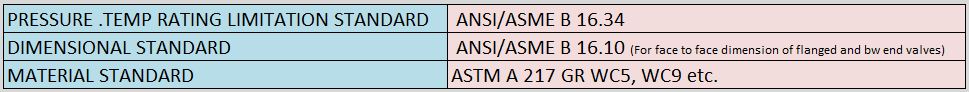

4. Cast Fittings:

Casted fittings like valves come into this category.

Leave a Reply