Carbon steel and alloy steel pipes when exposed to environment it combines with oxygen and water to generate rust (Fe2O3). To stop this problem high percentage of nickel (NI) and chromium (CR) is added to steel as below.

“Chromium (CR)- minimum 16% & nickel (NI)-minimum 8%”

Chromium is the alloying element which makes the steel “stainless”. Chromium when added to steel in high quantity , it reacts with oxygen available in air and water and spontaneously forms a self repairing microscopic thin inert layer of chromium oxide on the surface of steel. This layer resists further corrosion by not letting oxygen to react with the inner layer of steel. This gives stainless steel its resistance to oxidation- corrosion.

However nickel is the alloy which makes the stainless steel so widely used in all application. When addition of chromium makes steel lose its toughness nickel compensate for this. Chromium also induces magnetism but addition of nickel make it non magnetic which is highly desired in some application.

Nickel makes the stainless steel easy to form and weld. They are ductile at low temperature and also can be used for high temperature. Addition of nickel makes the ordinary steel which has a ferrite-body centred cubic structure to austenitic steel which has face centred cubic structure.

Well known stainless steel grade 304 is the standard 18-8 austenitic stainless steel and is the most widely used stainless steel.

Grade 316 is the standard austenitic grade that has molybdenum. The molybdenum gives 316 batter overall corrosion resistance properties than 304 grade particularly higher resistance to pitting (defect like indention) and crevice corrosion. 316 grades also give excellent toughness even through cryogenic temperatures.

Now let’s go to the other two grades 321 and 347 which are used for high temperature range.

In stainless steel the heat from weld sensitizes the base metal heat affected zone. Sensitization is the condition where “chromium” which was previously in a state of solution gets out and forms chromium carbide (which is a solid state) near the grain boundaries. Due to this chromium carbide formation the chromium content in stainless steel solution decreases. And as previously discussed chromium is the main element for steel being stainless and reduced amount of this means steel is susceptible to grain boundary corrosion.

The temperature range for sensitization to occur in austenitic stainless steel is 700°F (371°c) to 1500°F (537°c). To protect stainless steel from this phenomenon the below described ways are used-

“First way-Use a low carbon grade stainless steel like 304L or 316L”

To form chromium carbide chromium inherently need carbon. As there are less carbon available in this L grade chromium will form less chromium carbide. However with enough heat sensitization can still occur.

“Second way-Use a chemically stabilized grade of stainless steel like 321 or 347”

Titanium (TI) is added for 321 and Columbium (CB) is added for 347 grade with the intention that It will form Titanium or Columbium carbide rapidly without giving chromium and carbon a scope to form chromium carbide .this leaves chromium level intact in previous solution. However chromium can form some amount of chromium carbide in the temperature range of 700°F (371°c) to 1500°F (537°c).

“Third way-Thermally stabilize the above chemically stabilized grade of stainless steel like 321 or 347”

Thermal stabilisation occurs by heating the chemically stabilized stainless steel (321 and 347 grade) to a temperature approximately 1625°F (885°c) with hold time typically 4 hrs. This process forms titanium or Columbium carbide preferentially and resist formation of chromium carbide. This is common and 321 and 347 grade is purchased in the thermally stabilised condition and placed in service as welded means no heat treatment needed after the welding process.

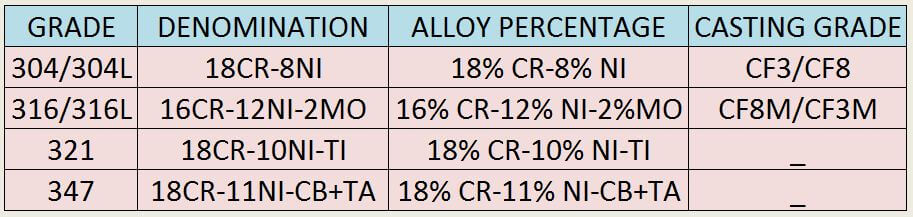

Types of stainless steel commonly used for process industry listed below.

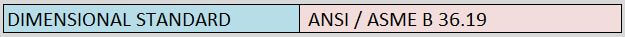

For each types of stainless steel piping element common ASME material standard and dimensional standard are provided below.

1. SS Pipes:

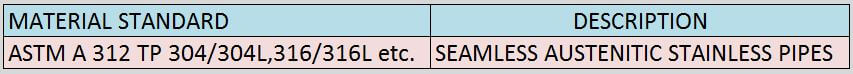

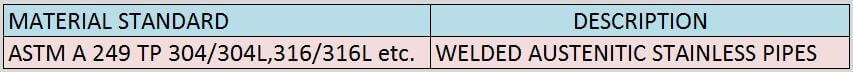

Commonly used SS pipes material standard:

Seamless pipes:

Welded pipes:

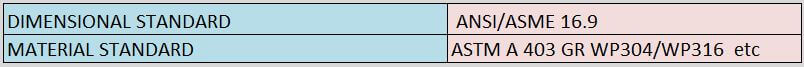

2. Wrought fittings:

Factory made Butt welded Elbow, tees, cap, Reducer etc. comes into this category.

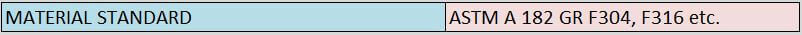

3. Forged Fittings:

Forges fittings like Flanges, sockolet, weldolet, Half Coupling, Forged valves comes into this category. For all of these forged fittings the material standard is one where as the dimensional standards varies.

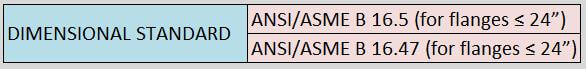

(a). Flanges:

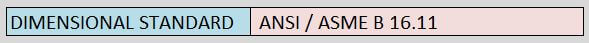

(b). Socket weld and screwed weld fittings:

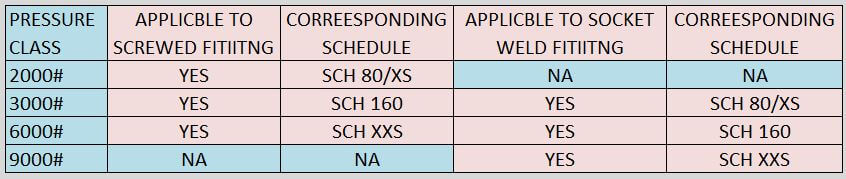

Four pressure class are available for these type of fittings

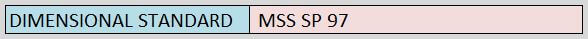

(c). Weldolet/sockolet:

4. Cast Fittings:

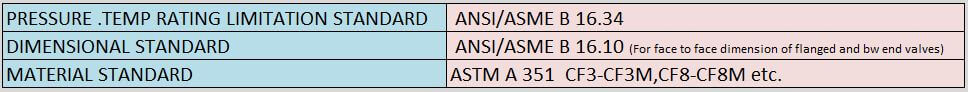

Casted fittings like valves come into this category.

Leave a Reply