Hydrotest pressure as per ASME B 31.3 para 345.4.2

The hydrostatic test pressure at any point in a metallic piping system shall be as follows:

(a) not less than 1.5 times the design pressure.

(b) when the design temperature is greater than the test temperature, the minimum test pressure, at the point under consideration, shall be calculated by eq. (24)

PT= 1.5 P Rr

Where:

PT =minimum test gage pressure.

P= internal design gage pressure.

Rr = ratio of ST/S for pipe or components without established ratings, but shall not exceed 6.5

=ratio of the component pressure rating at the test temperature to the component pressure rating at the component design temperature for components with established ratings, but shall not exceed 6.5.

ST = allowable stress value at test temperature

S = allowable stress value at component design temperature (see Table A-1)

(c) if the test pressure as defined above would produce a nominal pressure stress or longitudinal stress in excess of the yield strength at test temperature or a pressure more than 1.5 times the component rating at test temperature, the test pressure may be reduced to the maximum pressure that will not exceed the lesser of the yield strength or 1.5 times the component ratings at test temperature. [See paras. 302.3.2(e) and (f)

Hydro test calculation example-1

We need to find the hydrotest pressure of a piping system with below information

Design pressure of the piping system is 700 psi (48 bar)

The design temperature is 900°F (482°C)

Material- SS304

Pipe diameter and thickness – 6” NPS Sch 40.

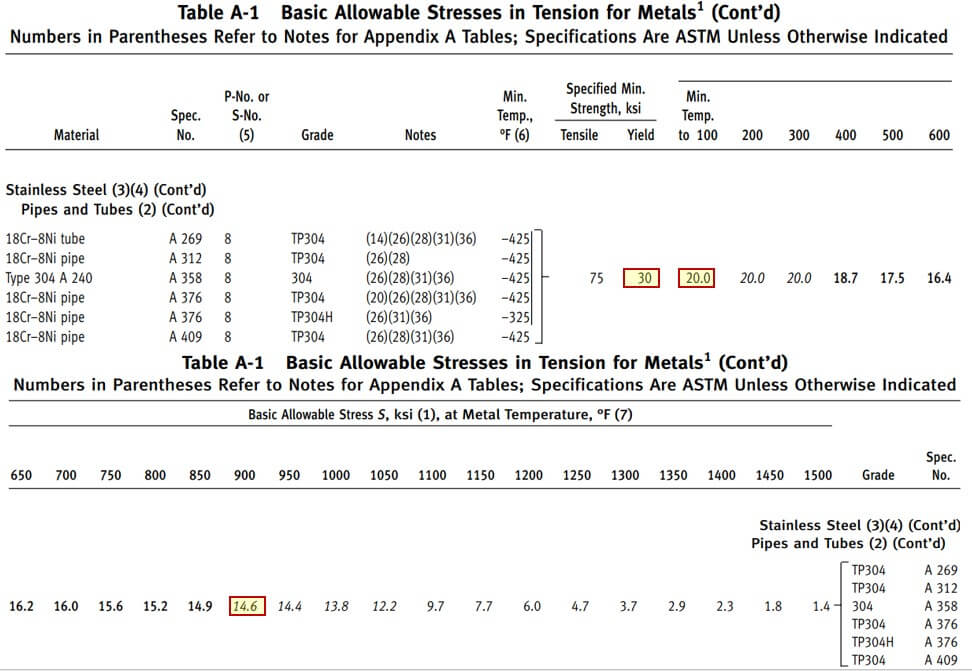

Step-1: Find the Value of Rr for components without established rating e.g pipe from B 31.3 appendix A, table A1

ST = allowable stress value at test temperature=20000 psi

S = allowable stress value at component design temperature=14600 psi

Rr (pipe) = 20000/14600= 1.4 (which is <6.5 )

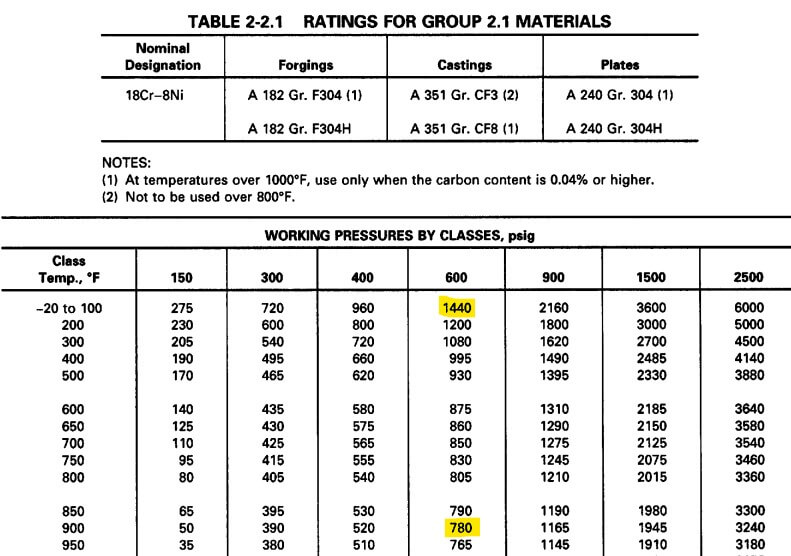

Step-2: For components with established rating e.g flanges find out the value of Rr from from B 16.5 working pressure table

From Asme B 16.5 table 2-2.1

Component pressure rating at test temperature=1440psi

Component pressure rating design temperature=780psi

Rr (Flange) = 1440/ 780= 1.8 (which is <6.5 )

Step-3: Find out the hydrotest pressure from Asme code eq. 24 for both established and unestablished components.

PT ( Pipe) =1.5 x 700 x 1.4 = 1470

PT ( Flange) =1.5 x 700 x 1.8 =1890

The minimum test pressure shall be the higher among the above , i.e 1890 psi.

Step-4: Check if the test pressure as defined above would produce a nominal pressure stress or longitudinal stress in excess of the yield strength at test temperature or a pressure more than 1.5 times the component rating at test temperature.

Calculate the stress above hydrotest pressure as per Step 3, will produce considering the thickness of pipe from below equation

S=PD/2t where

S= Allowable stress in psi

P=pressure in psig

D=Outside dia of pipe in inches

t= Thickness of pipe in inches

S=1890 x 6.625 / (2 x 0.28) = 22359 psi which is less than 30000 psi the yield strength of SS304 pipe per table A1 .

Step-5: Check if the test pressure as defined above would produce a pressure more than 1.5 times the component rating at test temperature.

1.5 x 1440 psi (Component rating at test temperature)= 2160

So Test pressure 1890 psi < 2160 (1.5 times the component rating at test temperature)

So final hydrotest pressure is 1890 psi as defined in Step 2 holds good for Step 4 and step 5 , so this shall be our final hydrotest pressure.

Hydrotest calculation example-2

We will see an example for 345.4.2 (C), where the test pressure need to be reduced to the maximum pressure that will not exceed the lesser of the yield strength or 1.5 times the component ratings at test temperature.

Suppose in above example-1 information the pipe size used is 20”NPS Sch40 instead of 6” NPS,

Then step 4 will produce

Step-4: Check if the test pressure as defined above would produce a nominal pressure stress or longitudinal stress in excess of the yield strength at test temperature or a pressure more than 1.5 times the component rating at test temperature.

S=PD/2t

S = 1890 x 20 / (2 x 0.5) = 37800 psi which is greater than 30000 psi the yield strength of SS304 pipe per table A1.

In this case the test pressure to be reduced to the maximum pressure that will not exceed the lesser of the yield strength or 1.5 times the component ratings at test temperature

Max pressure that would not exceed yield strength may be calculated per below

P=2tS/d where

P = 2 x 0.5 x 30000/20 =1500

Also the component rating at test temperature per step 5 is 2160psi.

Since 1500 <2160, 1500 psig should be treated as the Maximum hydrotest pressure.

References:

Phillip Ellenberger, 2010, Piping and pipeline calculation manual, Butterworth-Heinemann

Leave a Reply