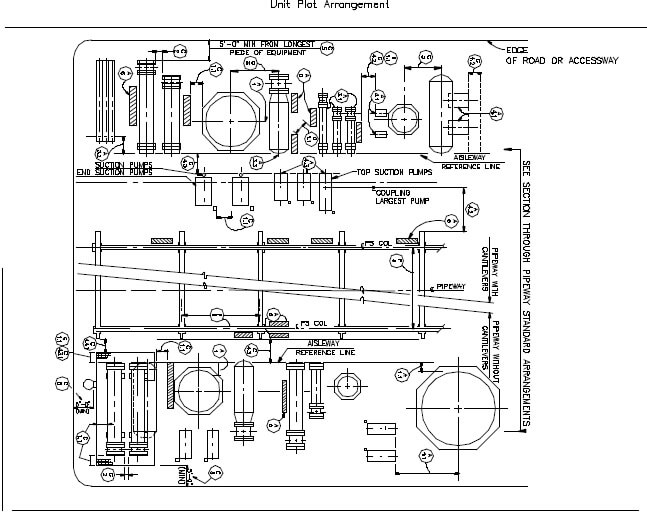

Definition of plot plan-

- It is a master plan locating each unit/facilities within the plot boundary.

Plot plan identifies all the component by designated numbers, shows the basic shape of equipment, supports and their location by plan view and if required then by elevation view.

For large process and chemical plants sometimes the equipment general arrangement drawing is also called the plot plan.

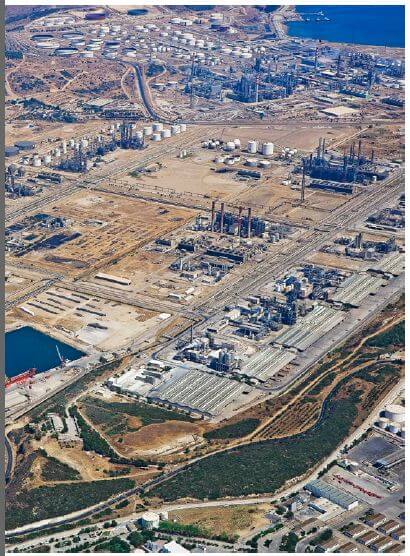

Below is a plot plan snap.

Here we will look at some data to be collected from different departments before starting plot plan

From Civil department:

1. Plane Table survey map:

Plan table survey map will show below things

(A) Location of Plot

(B) Existing infrastructure/road/river/temples etc present in 20 mitre extent to boundary of plot.

(C) True north direction

(D) Location of water and power connection.

2. Contour survey map:

Contour survey map will show Elevation of plot with reference to mean sea level. It will help in deciding for grading activity and location of facilities which require in lower level for e.g. Effluent treatment plan.

3. Soil survey:

It will mention the load carrying capacity of soil for e.g. 10 MT/cm for piping. It will help in designing the foundation for various structures. The requirement of piling can be decided upon it if the capacity is less.

From electrical department:

4. The location of supply and receiving Station

From Process department:

5. Size of process Unit

6. Indoor or outdoor requirement of facilities.

7. Products receive, Storage and dispatch philosophy:

based upon which we can provide suitable space for railway/truck loading/unloading area .intermediate tank or silos can be decided based upon storage requirement.

8. Sequence of Process flow:

Documents like Process flow diagram will be required for locating all equipments with proper interconnectivity.

9. Utility data:

This document will provide the source and supply of different utility like cooling water, steam, nitrogen etc. It will also state at what temperature/pressure condition they are available. Based upon these Utility equipments, Interconnecting utility piping and location of facilities which have utility requirements can be decided.

From Client:

10. Sizes of Non-plant Building:

Size of Admin/office facilities, canteen building, Workshop, gate need to be collected.

11. Statutory requirement:

All governing codes and standards to be followed need to be known.

12. Metrological data:

Metrological data like the maximum/minimum rainfall level, highest flood level, wind direction, seismic zone are required for the area where the plant is going to be located.

13. Expansion philosophy:

This will help in reserving the area for future facilities.