Indian Boiler Regulation usually referred as IBR is a set of standards that regulates the materials, design and construction, inspection and testing of boilers and boiler components . It is mandatory for the manufacturer and users of boiler in India to follow this regulation.

If there is boiler/steam generation/steam distribution piping system in the project scope, the IBR piping package need to be created and the user should get it approved from concerning authority.

Here we will see which equipments and piping comes into the purview of IBR piping.

1. Identification of equipment that should comply with IBR:

(A) Any closed vessel with capacity more than 22.5 litres which is exclusively used for generating steam under any pressure for process, and include any mounting or other fittings attached to such vessels which are wholly or partially under pressure when steam is shut off.

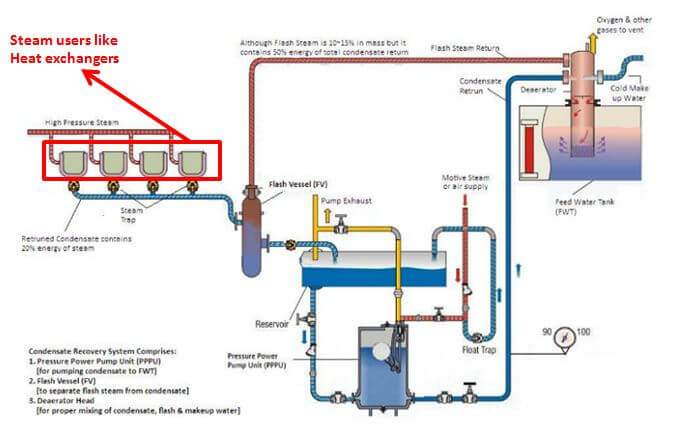

(B) Any steam user condensate from which is used in flash drum for processing steam for further use. For e.g heat exchangers/vessels/condensate pots as shown in below figure-1 will come in IBR scope.

But steam users where outlet condensate is drained to atmosphere or flashed to atmospheric pressure (as in deaerator) and vented (without isolation) do not come under IBR purview. The IBR specification break in such cases is done at last isolation valve on the steam line upstream of equipment.

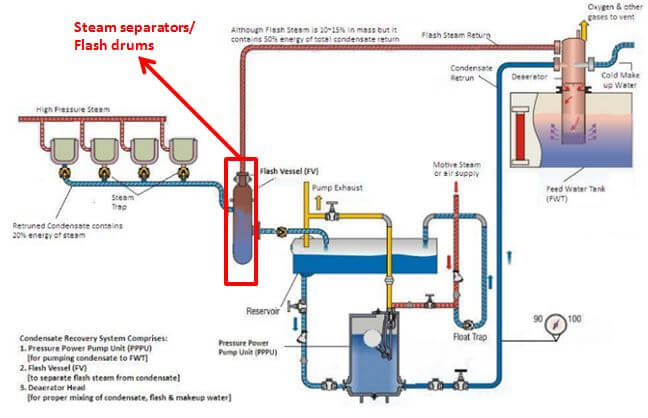

(C) Any equipment which receives steam condensate to produce flash steam for further use in process will come under IBR purview irrespective of pressure and quantity of steam produced.

For e.g steam separators and flash drums as shown in below figure-2.

But if the same equipment receive condensate to produce flash steam that is vented to atmosphere (without isolation) will not fall under IBR purview irrespective of pressure and quantity of steam produced.

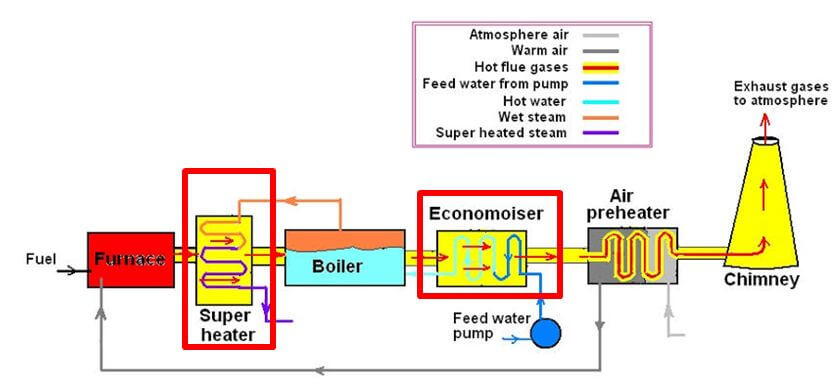

(D) All steam economizers and steam super heaters come in IBR scope. see Fig-3

(E) All steam users where the outlet condensate piping is connected to IBR equipment are covered under IBR. In case of steam turbine even if the condensate is connected to IBR equipment, the steam turbine is not covered under IBR.

(F) Deaerator operating at 1.05 kg/cm2 pressure and the boiler feed water pump do not fall under IBR purview. All steam users where the outlet condensate piping is connected to IBR equipment are covered under IBR. In case of steam turbine even if the condensate is connected to IBR equipment, the steam turbine is not covered under IBR.

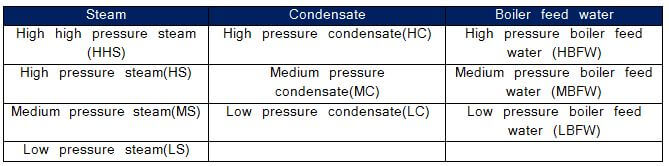

2. Identification of piping systems that should comply with IBR:

(A) All steam and condensate line for which the design pressure exceeds 3.5 kg/cm2.

(B) All steam and condensate line greater than or equal to 10”NB for which the design pressure exceeds 1 kg/cm2.

(C) All steam and condensate line interconnecting IBR equipments are classified under IBR purview.

(C) Boiler feed water pipelines from BFW pump to boiler.

(C) Generally these below piping services follow IBR

(C) Generally these below do not come under IBR purview

I) Steam tracing piping

II) Heating coils and heating tubes in tanks.

III) Steam jacketed piping.

Saru Vanan

We have a steam heat exchanger to which steam of pressure 3.0 kg/cm2 is supplied through a 1″NB pipe. The output of heat exchanger is connected to a steam trap and the condensate is collected through condensate recovery system and sent back to feedtank’s dearator.

My question whether this “Steam exchagner” comes under purview of IBR?

thepipingtalk

Hi saru, I don’t think that HE comes under IBR purview, as condensate is brought almost to atm pressure before sending to deaerator and I believe inside deaerator also it’s not such high pressure. When the condensate has enough energy left such that the flash steam also can be utilized for further process then only that HE will be under IBR. Any 2nd opinion will be appreciated. Ty

Saru Vanan

Thank You

Sankar

hi the pipiingtalk, it would be nice if you can refer to the particular regulations which tell us this.

Vaman Arakeri

As per IBR is it necessary to mount PSV directly on steam drum nozzle

M krshavamurthy

Sir I want to know the pipe size ibr pipeline upto 130 MTR from 850kg boiler

thepipingtalk

Dear keshav, Sorry not much idea on sizing.

Query us Open to all visitiors if any help on this..

Abhijeet

Good information

Tapas Ghosh

I have a system of 20KL closed reaction vessel. It is low pressure vessel working at 2 – 3Kg/cm2(g). A water based Slurry is heated up by steam coil inside and the reaction mass is allowed to hold up for about 2 hours at around 150 Deg.C. The steam generated inside vessel is vented into atmosphere once the batch is completed. The condensate from prime heating steam is collected in a condensate tank and transferred to boiler feed water tank.

Will the Vessel come under IBR?

thepipingtalk

Hi Tapas, in my understanding – as the vessel is not exclusively used for generating steam, it should not be under IBR purview. it can be classified as a steam user and also the condensate from it is not used to generate steam. thanks (reply if you found the opposite to be true)

Gagan Gopal

Please provide technical justification as per IBR , for steam tracing and steam jacketed piping does not covers under purview of IBR.

thepipingtalk

Hi Gagan, Thanks for visiting. below is a snap from PDIL spec which states the same.

https://thepipingtalk.com/wp-content/uploads/2022/05/pdil-IBR-related.jpg

Vikas

Nice information

Priyesh Agrawal

Hi Piping Talk, Thanks for the above article clarified many doubts.

Is there any document which can be used as reference for discussion ?